Latch Lock

Latch conveyors are mechanical elements that are inserted into injection moulds in order to control the movement process of multiple separation levels when opening the mould. They enable synchronised or delayed opening of separation levels, which is necessary particularly for complex geometries or undercuts. Thanks to their low moving mass, they achieve rapid opening and closing movements, which also makes them suitable for high-speed tools.

Slider technologies

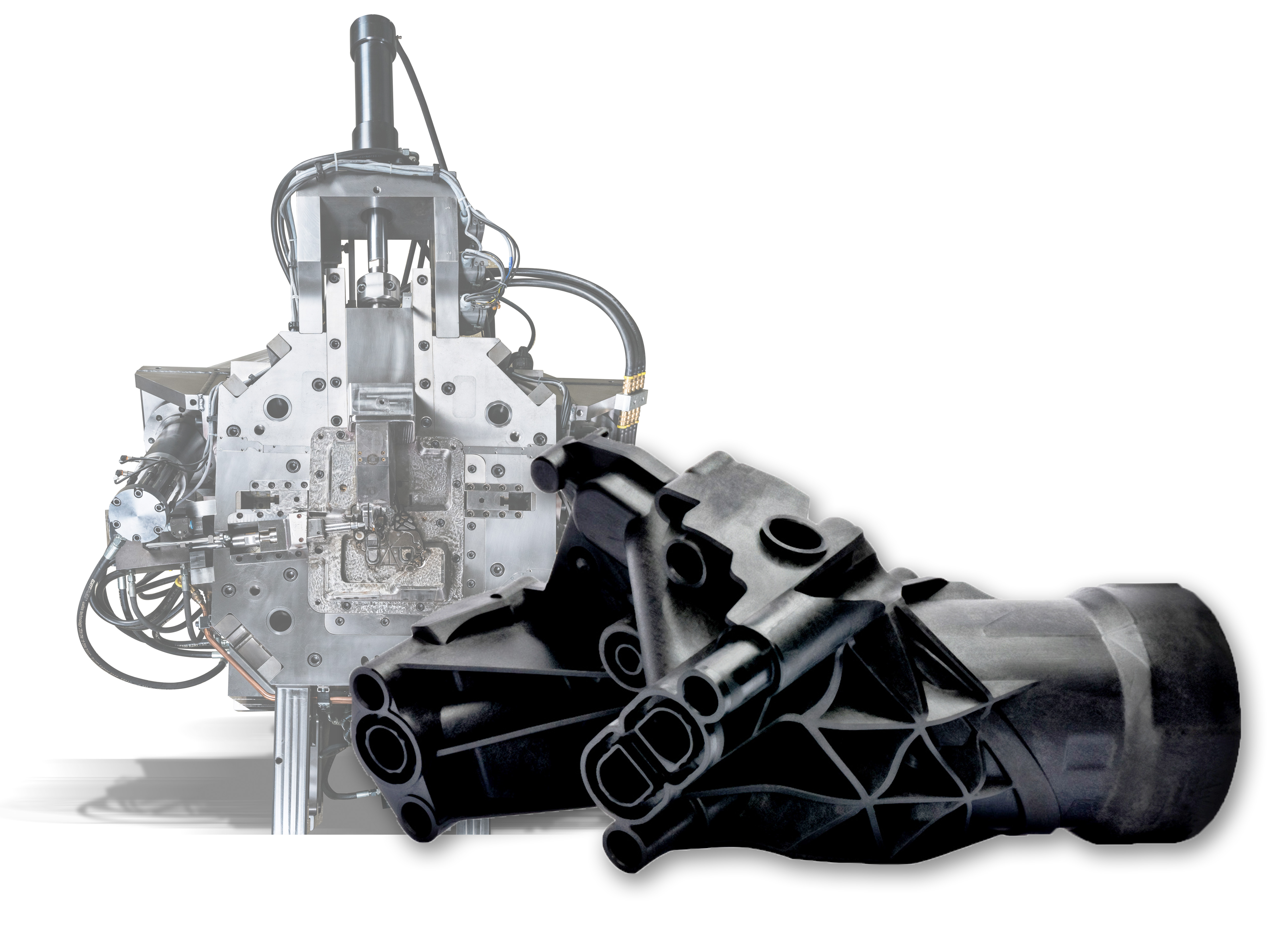

Sliders are one of the core elements of tool manufacture when it comes to demoulding complex plastic components.

Complex product geometries:

We implement slider solutions to ensure reliable demoulding even for complex components. We have already successfully implemented multiple slider-in-slider concepts to handle particularly challenging geometries.

Multi-component tools:

Other applications include gate valves or rotary slide valves in multi-component injection moulds. They separate individual cavities or areas from one another and ensure that the different materials in the workflow are processed exactly at the intended points. This makes it possible to manufacture high-quality 2K and multi-component products with high dimensional stability and functional security.

Translation and displacement technologies

This technology involves shifting the substrate into a second cavity after the first injection process – either using integrated offset sliders or external handling systems. The overmould with the second component is accomplished in this new location.

The advantages for you: optimal flexibility in tool design and the option of reliably manufacturing multi-component products even with challenging geometries or material combinations.

Index-plate-molds

For the manufacture of 2K plastic products, the index plate tool is a particularly efficient solution. In this process, the first component is injected into the tool and then transported into the next cavity by a rotating index plate. The second injection process is carried out there in the same tool.

This has multiple advantages for you: The substrate does not need to be removed or repositioned, which cuts back on handling times and increases process reliability. At the same time, precise alignment of the index plate ensures an exact fit and consistently high quality, even for challenging components and complex geometries.

This results in high-quality multi-component products with optimal functionality and a sophisticated look – cost-effective, reliable and precisely tailored to your project.

Unthreading solutions

Internal or external threads pose a particular challenge in injection moulding: Simple ejection would damage the component or make the thread unusable. One clean solution is spindle extraction.

This involves rotating the thread out of the product precisely after injection moulding. Using mechanical or motorised drives, the spindle retracts in a controlled manner and gently releases the component. This results in plastic components with precise, functional threads – without any follow-up work.

Collapsible core

Internal contours or undercuts – such as internal threads or circumferential geometries – often make it more difficult to demould a plastic product. In such cases, drop cores (also known as collapsing or collapsible cores) are an ideal solution.

The moving core segments retract before ejection and release the undercut. This allows the component to be removed from the mould cleanly, reliably and without damages – even with challenging geometries.

Conformal cooling

In modern injection moulds, cooling can be the key to increasing efficiency and improving quality. Our conformal cooling solutions introduce the tempering channels as close as possible to the mould contour, dissipating heat right where it is produced. This reduces hotspots and ensures a more uniform temperature distribution.

Your advantages at a glance:

- Considerably shorter cooling times – more parts per hour

- Reduced delay, better dimensional stability and surfaces

- More homogeneous mould temperatures – more stable processes

Individual solutions

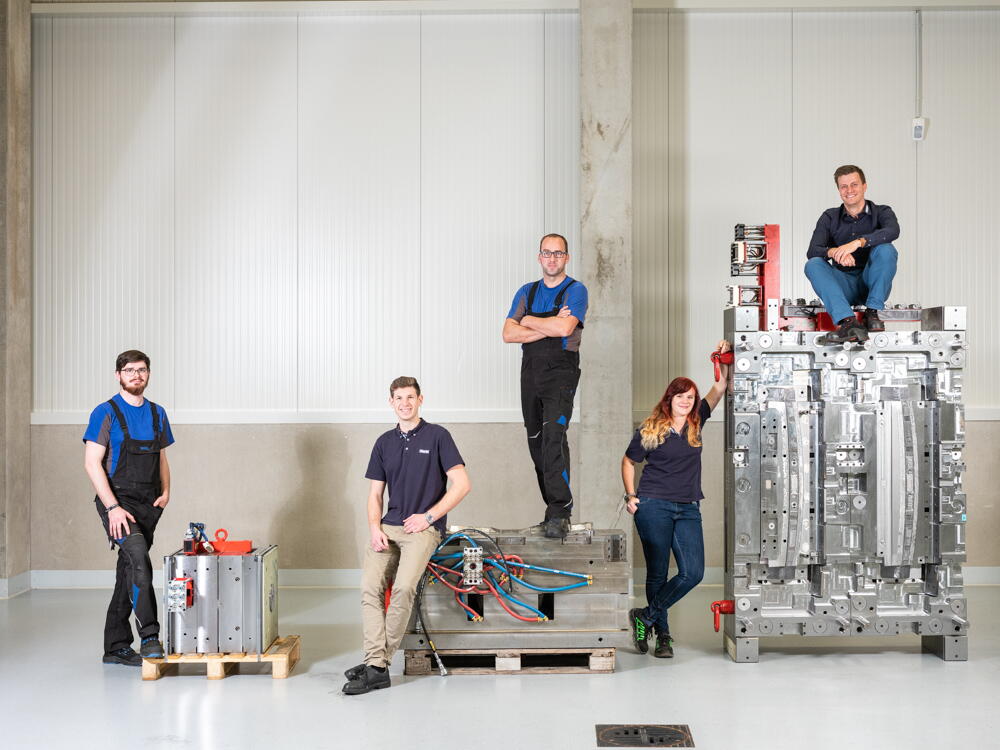

Every plastic component is unique – and sometimes a single standard technology is not enough to meet all the requirements. We develop tailor-made concepts with you.

Our team analyses your requirements, ensures feasibility and drafts an optimal solution – in this way, you receive a tool that is precisely tailored to your project, guaranteeing the utmost quality, function and efficiency.

1-component-molds

1K injection moulding offers a highly versatile range of manufacturing – from simple standard parts all the way to complex components with the strictest requirements. At AWM, we develop the right tool concept for each product, tailored to function, material and design.

Thanks to years of experience and numerous challenges that we have successfully resolved, we know exactly what it takes: precise design, reliable process management and consistently high quality. In this way, we ensure that your products are manufactured in a reliable, efficient and cost-effective manner.

Multi-component-molds

AWM offers years of experience and extensive know-how in the development of multi-component tools. We develop the perfect concept for your product, whether the focus is on functionality, design or complex material combinations.

The advantages for you:

- Custom solutions – precisely tailored tools for every product.

- Maximum precision – optimal manufacturing quality for complex components.

- Experience that counts – decades of expertise in design and process management.

- Flexibility in design – the perfect combination of function and look.

Family molds

Family moulds using injection moulding offer an efficient solution for manufacturing complex components in a single production step. In contrast to multi-cavity moulds which produce a large quantity of identical parts, family moulds enable simultaneous manufacturing of different components. This technology is particularly advantageous if multiple components for a product need to be manufactured simultaneously, for example modules with multiple components.

Back-injection

If your plastic component requires additional functions or decorative elements, back injection is an ideal solution. This involves inserting a decorative material – such as film, textile or metal film – into the injection mould and then overmoulding it with plastic. Mechanical engineering expertise.

This technology enables the manufacture of components with integrated surface structures that fulfil both functional and aesthetic requirements. They are particularly suited for applications in the automotive industry, electronics or household appliances, where design and functionality go hand in hand.

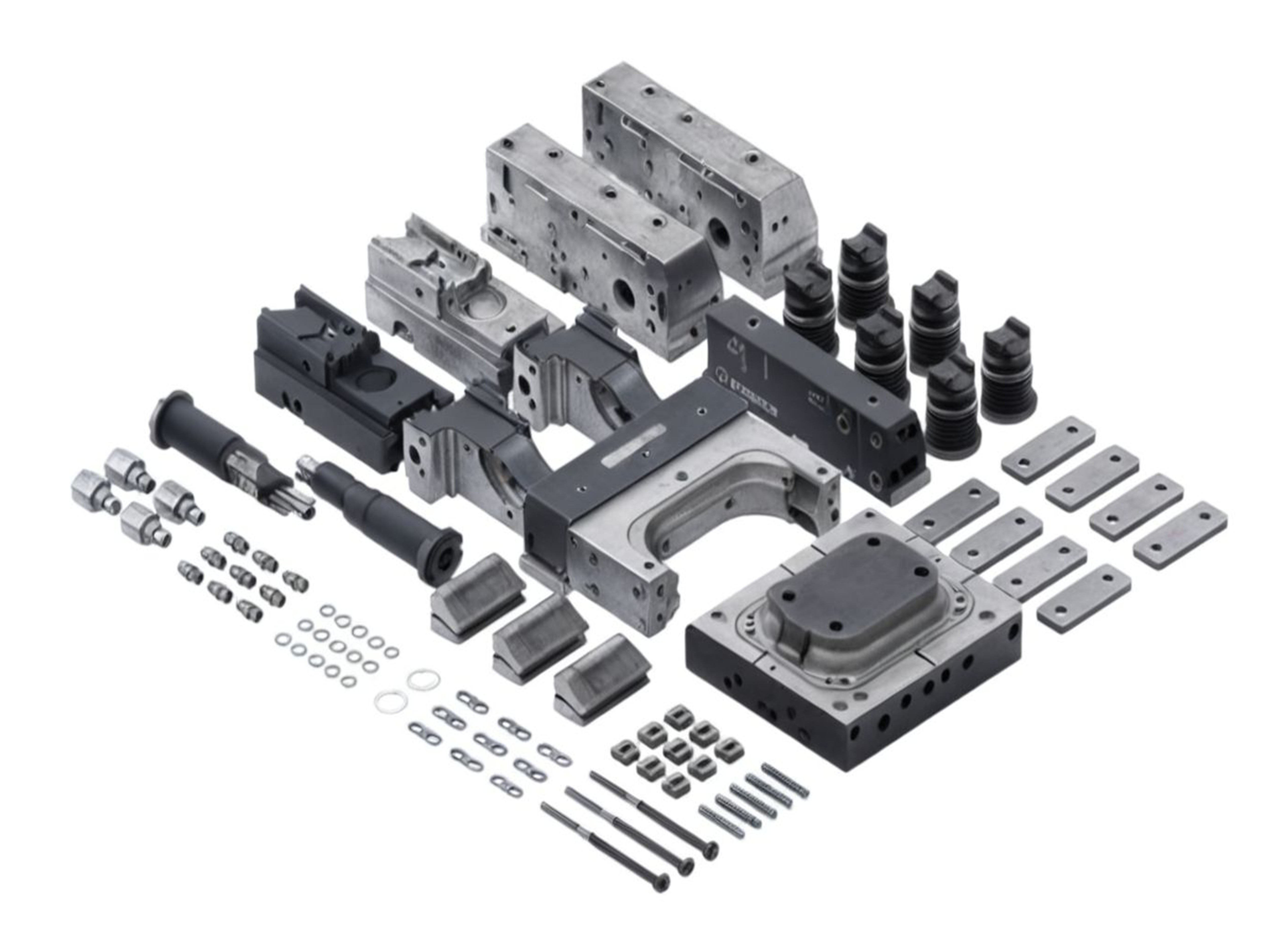

Inserts

Sometimes, a plastic component requires previously integrated components – for example aluminium bushings, copper plugs or other functional elements. These insert components can be positioned directly in the mould and overmoulded during the injection moulding process.

In this way, we combine the properties of plastic and metal into a single, precise component. Regardless of whether the focus is on electrical conductivity, wear protection or mechanical stability, we develop the right solution and reliably integrate your insert components into the injection moulding process.

High-temperature mold

Certain plastics such as PEEK, PSU or other high-performance thermoplastics require particularly high mould temperatures for injection moulding. To ensure that your products can be manufactured precisely and reliably under these conditions, we design and construct special high-temperature moulds.

In this context, we consider not only the high thermal stress but also the required safety and insulation standards. This allows us to ensure that your mould operates reliably and lasts a long time – even under extreme conditions.

Service

Optimal performance starts with a tool that works perfectly. That’s where our Tool Service comes in. Whether preventive maintenance, targeted refitting or acute repairs: We ensure that your tools remain operational on the long term and deliver consistently high quality.

Here you have an overview of our services:

Link

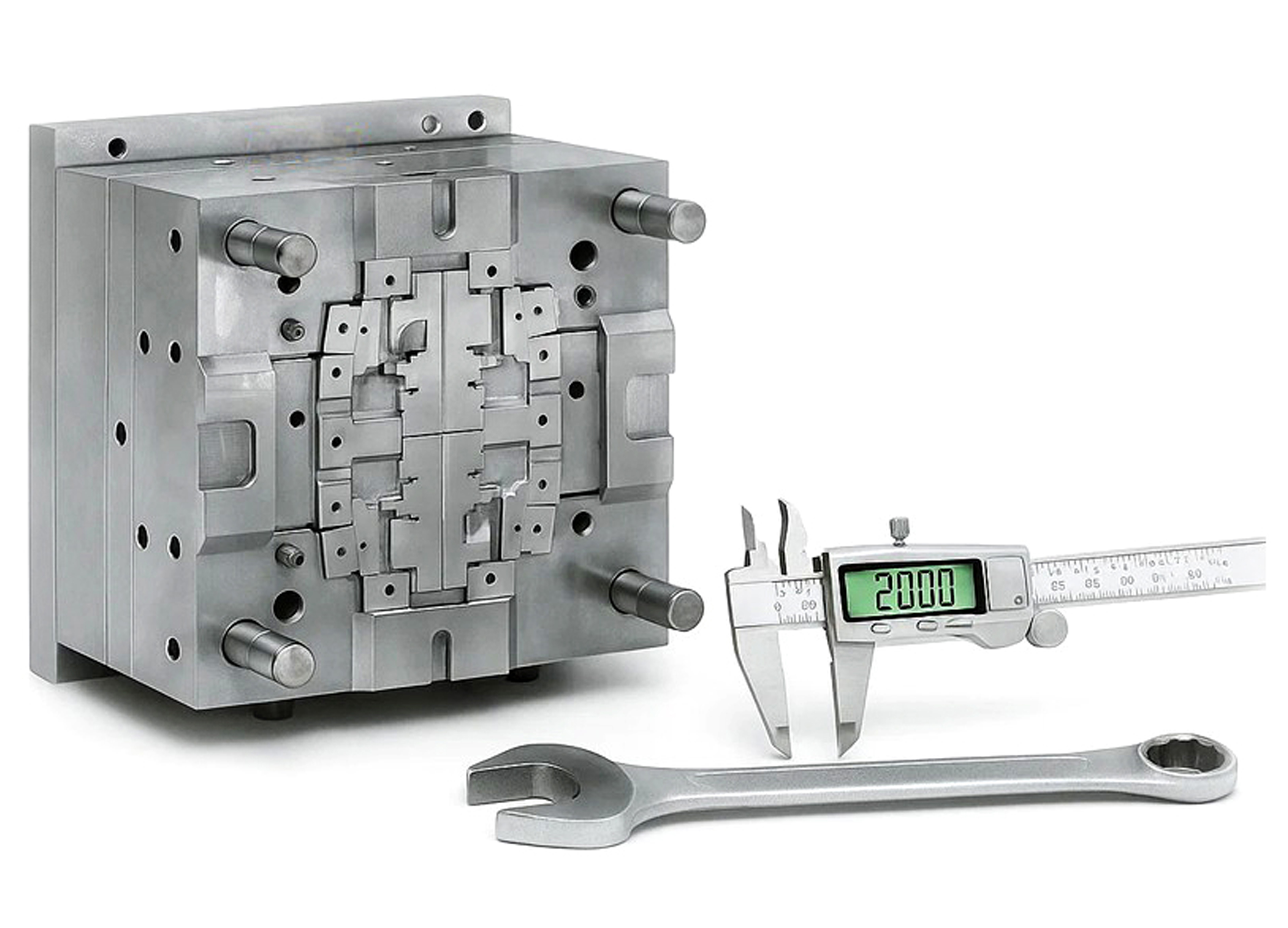

Our mould for your project

Your project is unique – and so are our moulds. Regardless of what requirements you have for your component, we develop and manufacture the right injection mould for you: precise, reliable and perfectly coordinated for your processes.

Design and construction of injection moulds up to a weight of 20 tonnes

- Moulds for high gloss and design components

- Moulds for technical components

- Multi-component tools (transfer, rotating, gate valve and offset technology as well as index plate tools)

- Stack moulds

- Monosandwich moulds

- Tools for film back injection technique

- Overmoulding of insert components