We develop special solutions that are as individualised as your requirements: each project unique, each machine tailor-made, always efficient and target-oriented thanks to our years of experience combined with modular, well-established concepts.

In-house developments for optimal performance

Our customers individual requirements have been transformed into smart, highly innovative products that are still used today, expanding our expertise in special machine engineering to include real best-practice solutions.

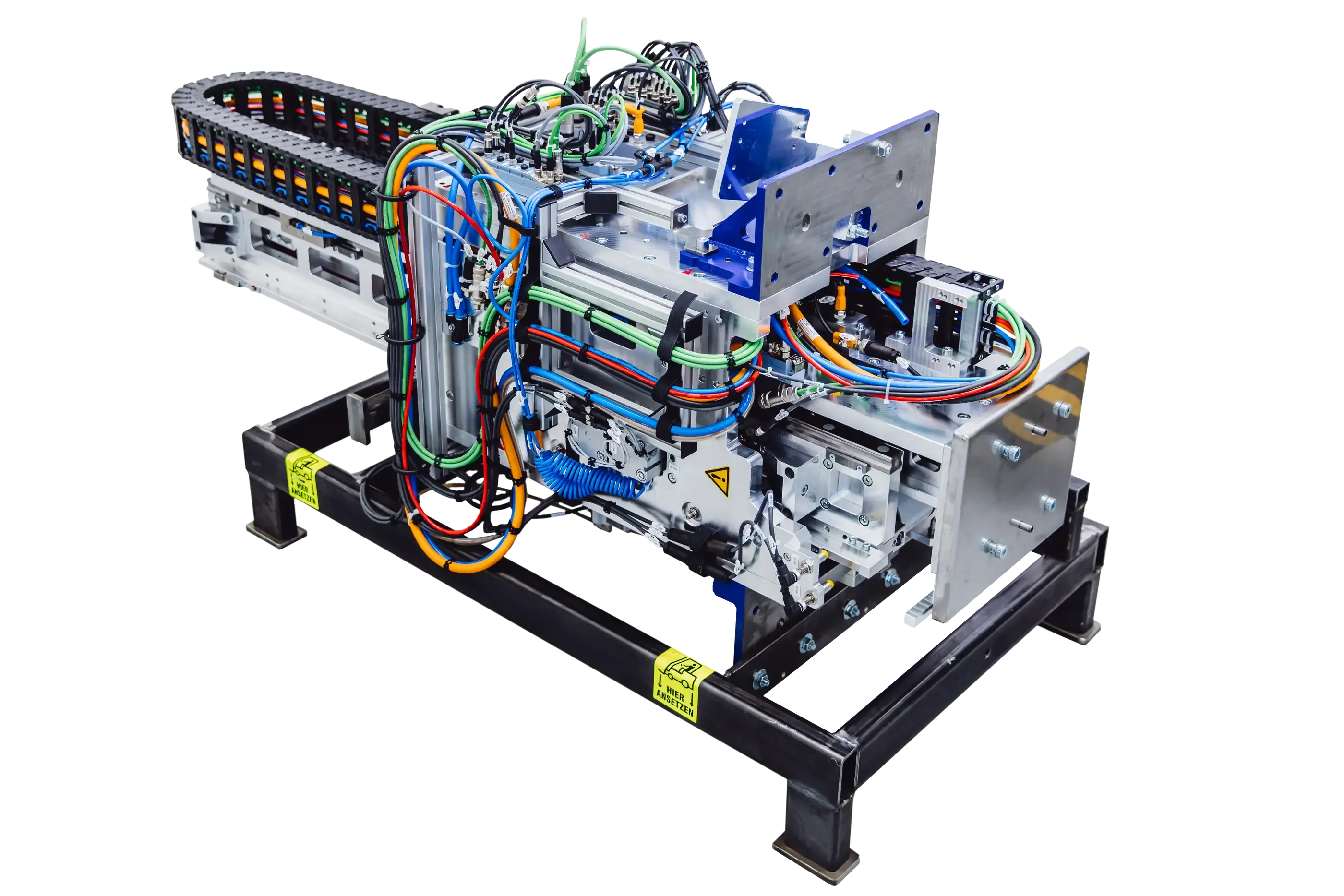

Telescopic Z-axis – Developed in-house for compact, high-precision designs

Our telescopic Z-axis was developed for applications where standard solutions are not enough: precise, dynamic and individually adjustable. The two-stage drive comprised of toothed belt and gear rack enables long strokes with a minimal installation height and high rigidity. The modular concept offers maximum flexibility for customer-specific requirements.

Advantages & Technology

The axis offers up to 40% reduced installation height, low noise and maintenance requirements, high repeat accuracy and various available sizes. It achieves strokes of up to 2,000 mm, can bear a load of 40–60 kg, operates at up to 1.5 m/s and offers repeat accuracy of ±0.5 mm.

Electrical equipment & options

A servo drive according to customer specifications, freely selectable installation levels, Profinet interfaces as well as CE and UL conformity are included along with integrated fall protection. Extensions such as swivel units or replaceable modules for grippers, joining or assembly tools can be integrated easily.

Typical applications

Typical applications include palletising trays, containers and panels, automated loading of processing and machining centres as well as various assembly and joining tasks.

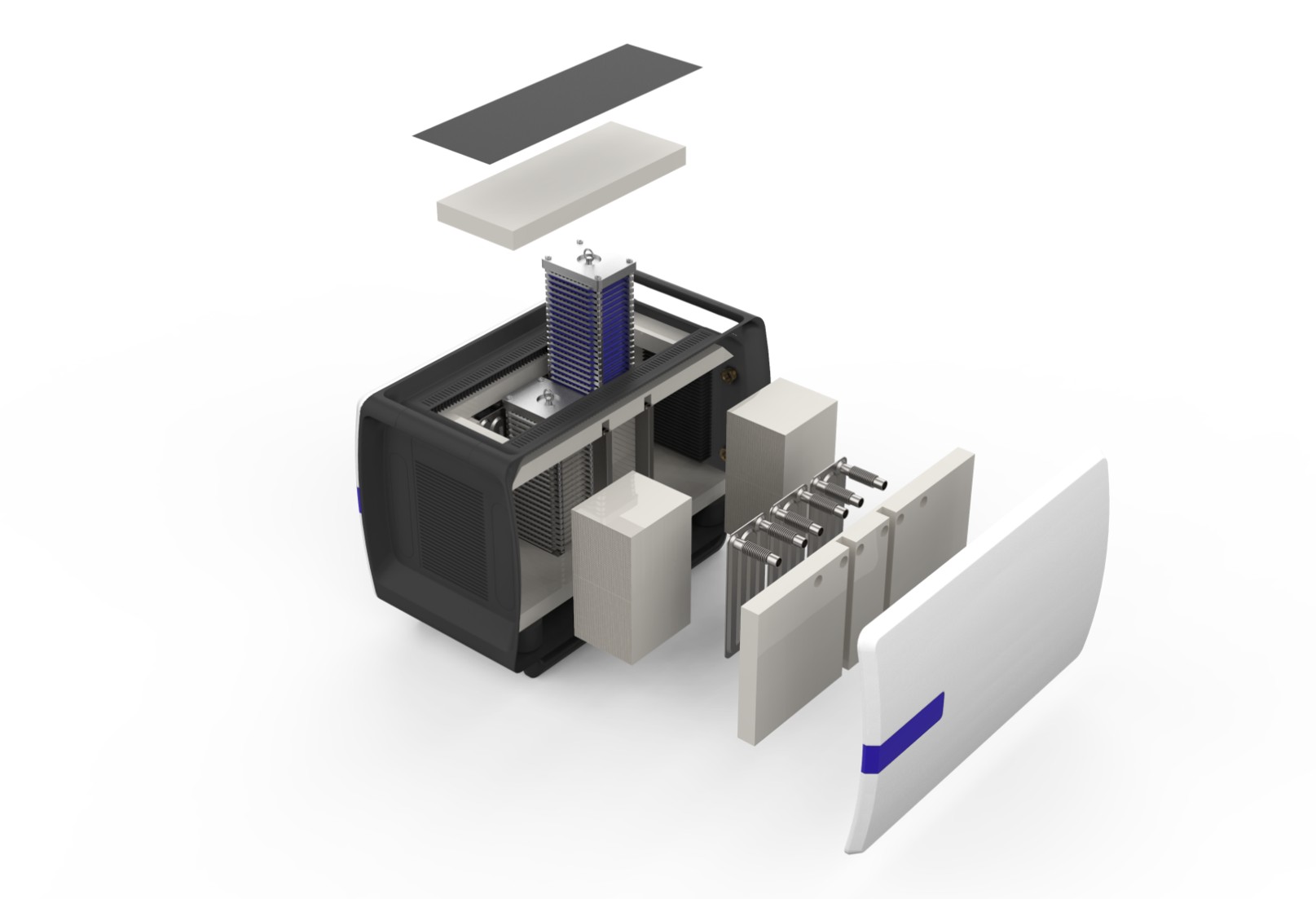

Cam-controlled platform – developed in-house for optimal performance

Increase cycle times – achieve success in 80 cycles

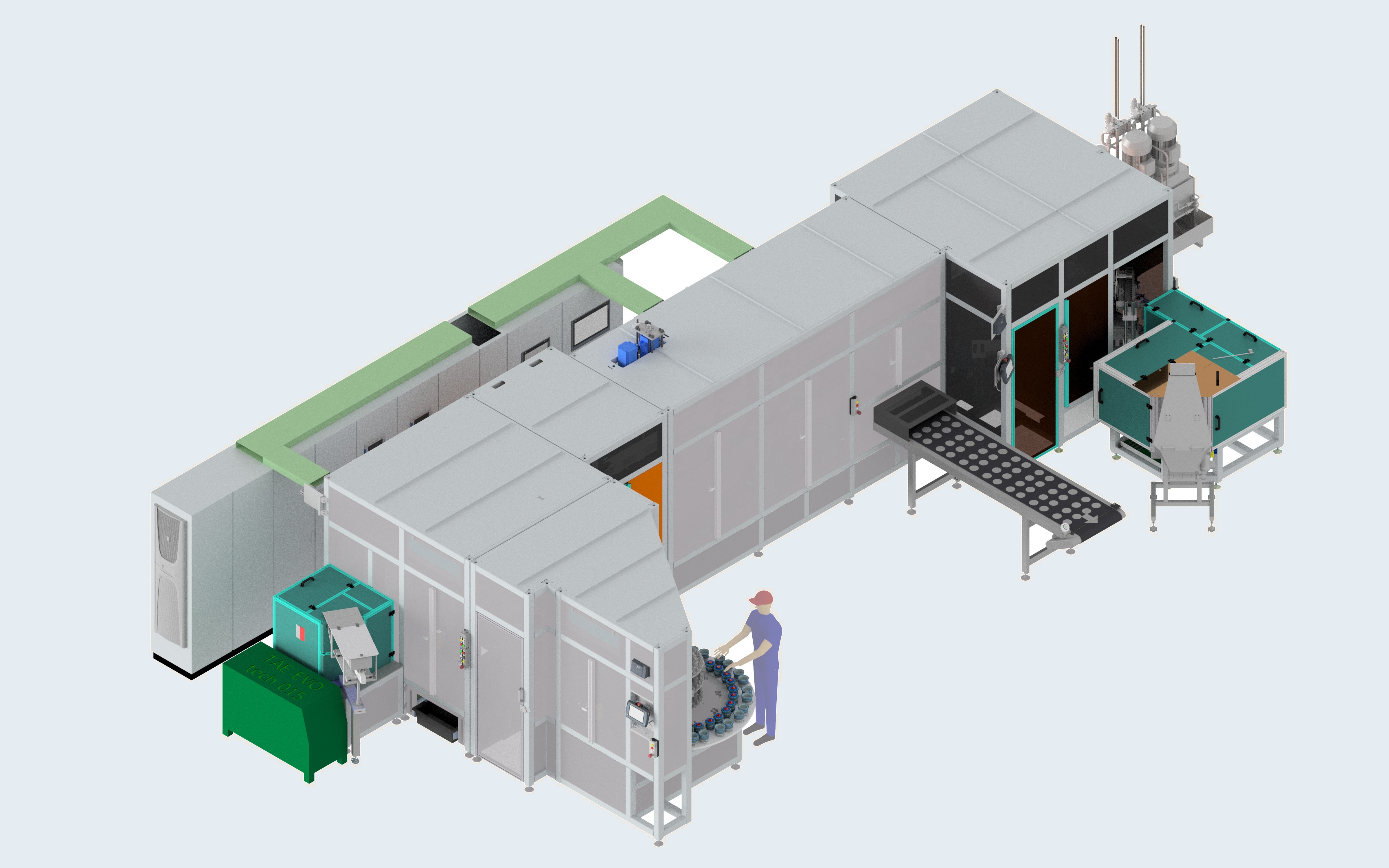

The AWM Cam-Driven Line (CDL) Depending on the requirements, three platform sizes are available with 16, 24 or 32 stations – perfect for challenging assembly, testing or joining tasks.

The linear machine platform delivers excellent accessibility, a sophisticated protective cladding system with integrated rooftop switch cabinet and a range of combinable handling modules. From the extensive AWM assembly kit, it is possible to configure Pick & Place units, assembly or testing technology based on the precise requirements.

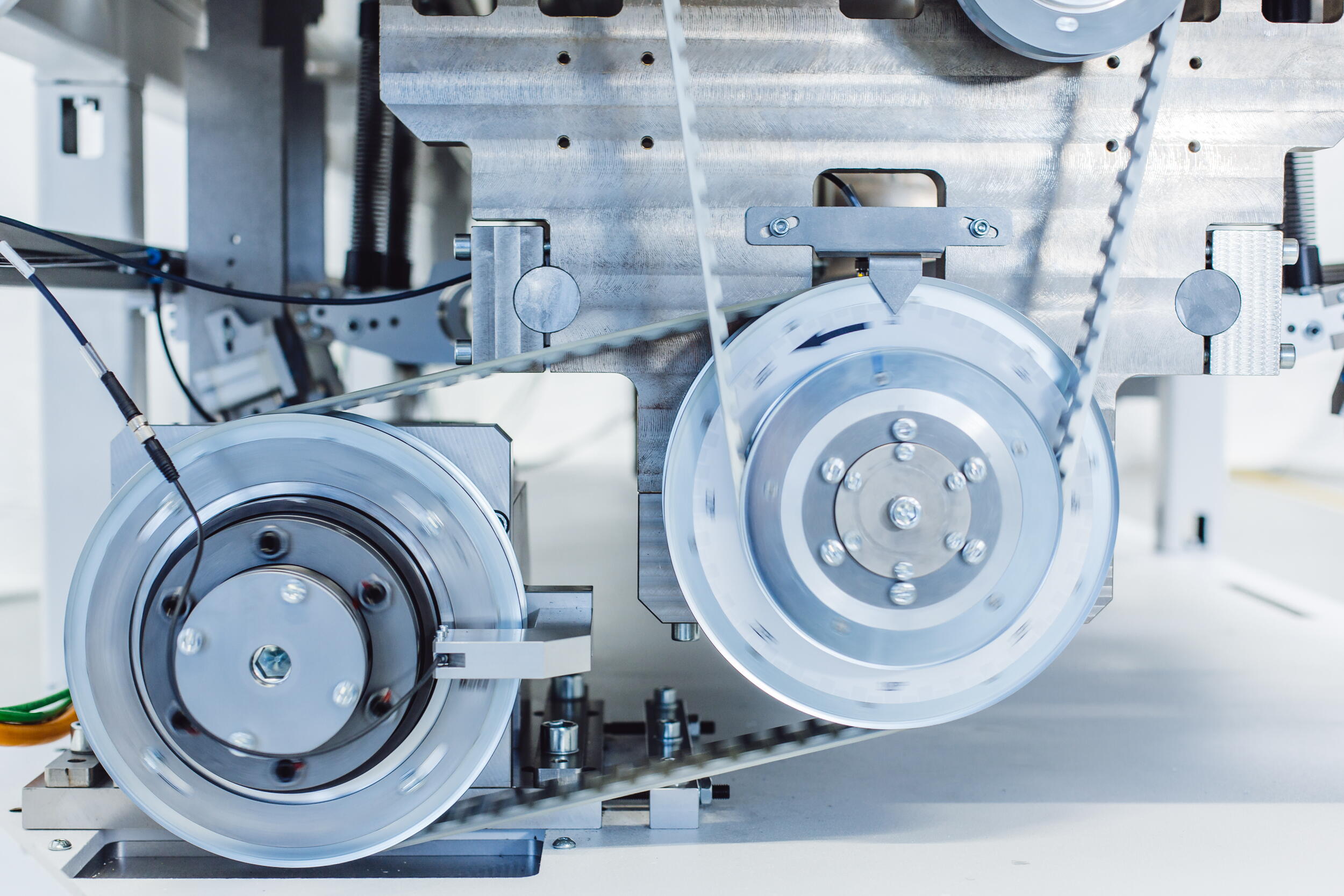

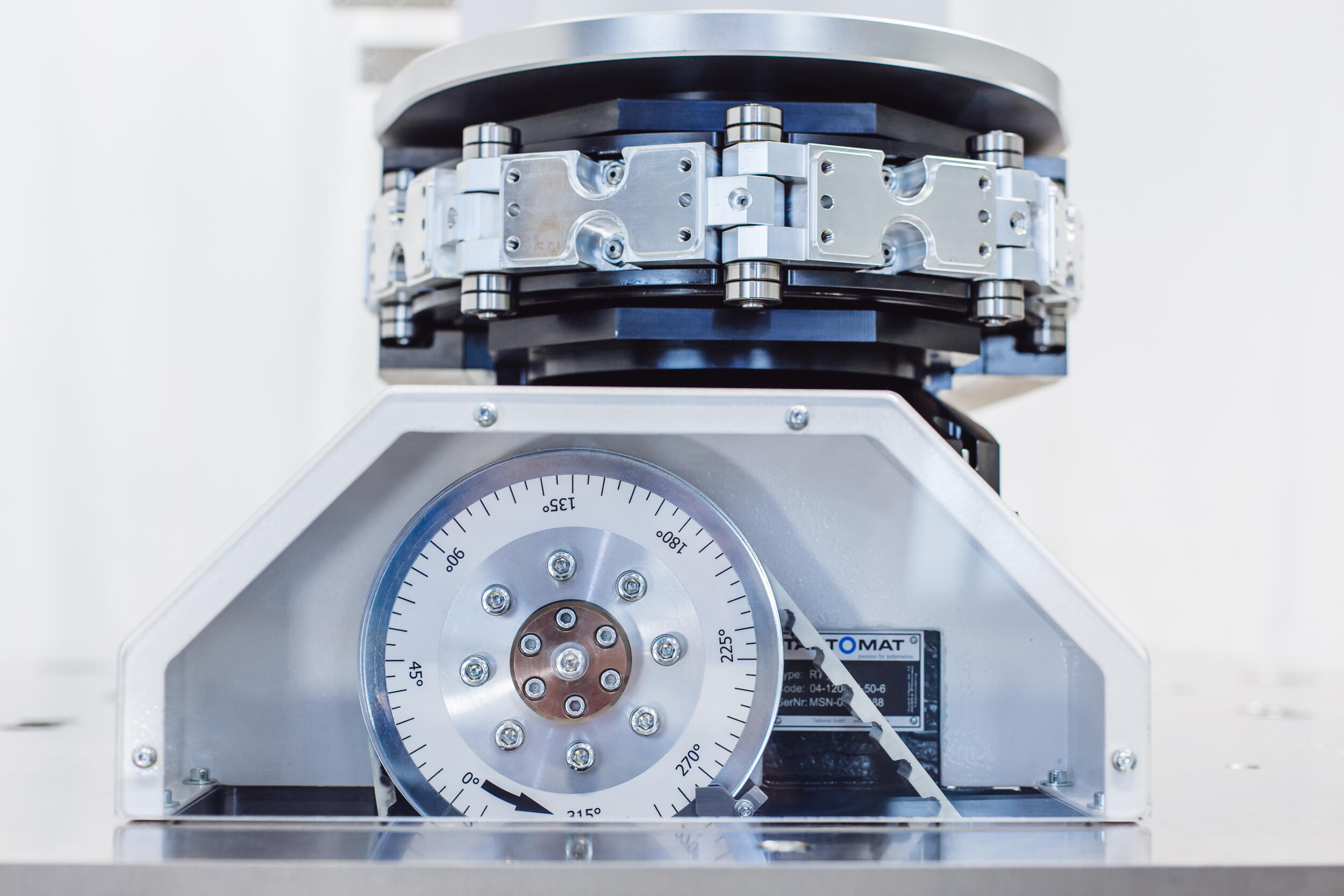

How the CDL works

A central drive using a toothed belt moves both the horizontal main shaft and the stepped motion gear. This propels the cycle chain, which operates at a preferred switching angle of 120° and provides four defined stopping positions. Below the table surface, cam discs control the movement profile of the stations. Using cam rollers and bell cranks, the linear and vertical movements are implemented precisely – using tension springs or pneumatic support depending on the design.

The advantages for you: maximum cycle performance, high process stability and an assembly-optimised platform that can be adapted to your exact production requirements.

New possibility of hybrid machines – integration also of electric or pneumatic driven stations in between the cam-driven stations, with reliable synchronisation. This provides a much higher flexibility, e.g. to produce different product variants, than would be possible with cam-driven stations only.

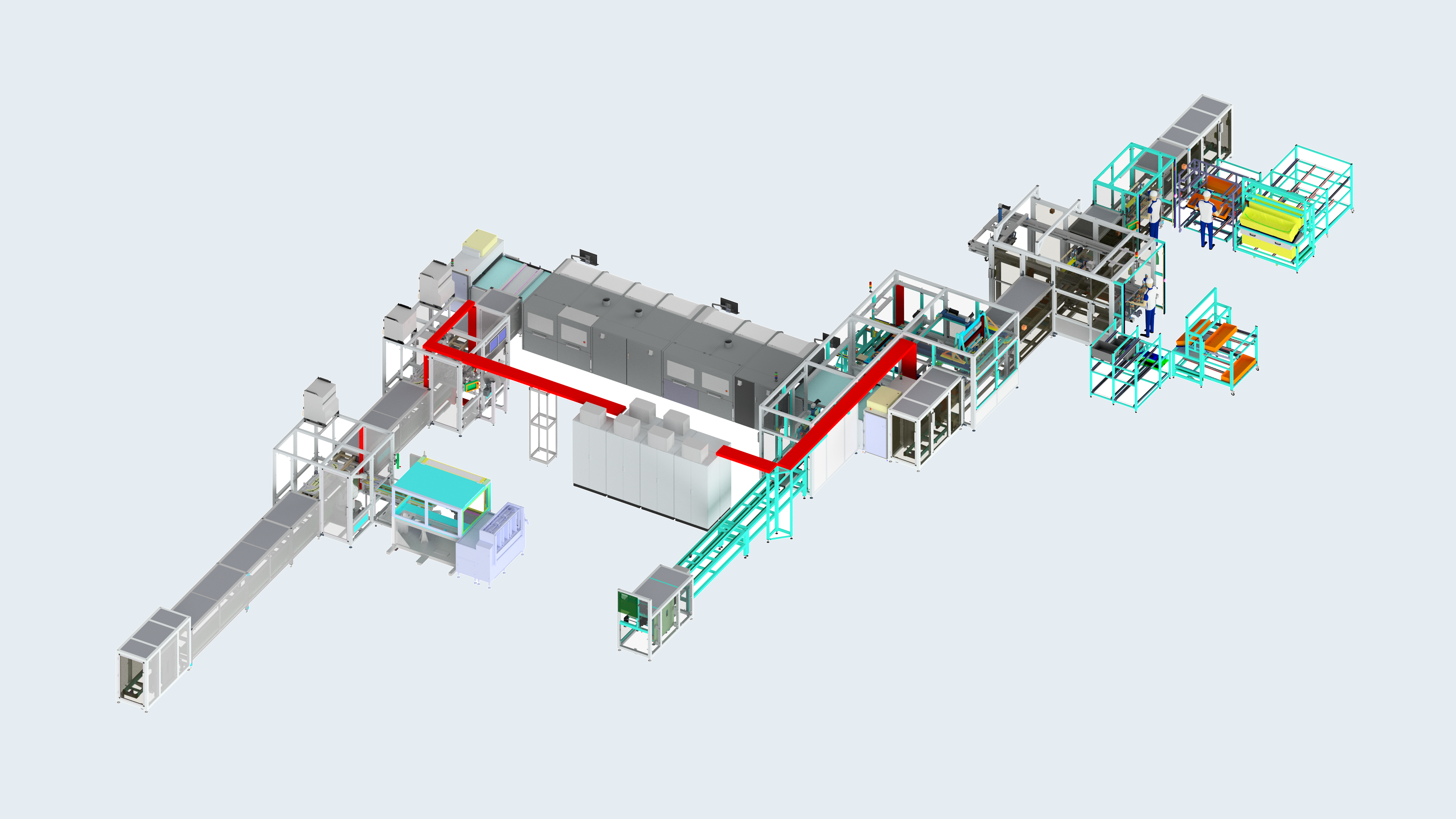

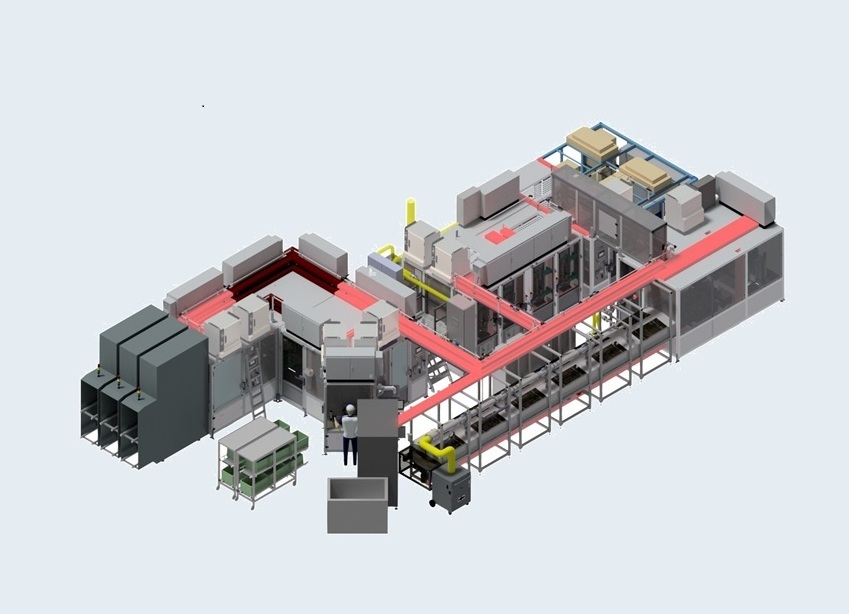

As your partner for intelligent production solutions, AWM GmbH offers powerful automatic assembly, testing, robotic and injection moulding machines for a wide range of industries. With our experience in integration, we combine established, standardised processes into an efficient overall system, ensuring reliable and fast production at a consistently high quality level. We rely on our decades of in-house expertise and strategically expand on our know-how by consulting selected external specialists. In this way, you always obtain the precise solution that optimally aligns with your requirements.

Our processes

Cases

AWM GmbH develops solutions that are precisely coordinated to your requirements, combining technical performance with economic efficiency. Our references demonstrate how we transform complex challenges into powerful, established system solutions. In the following, you will receive an overview of typical applications and selected use cases.

Customers

Do you have any questions?

We will resolve your issue.

The quality and reliability of our special equipment is primarily determined by the quality of our mechanical components. We consider ourselves to be your solution provider for assembly and testing systems as well as sophisticated machines for plastic/metal-oriented parts and mechatronic systems up to a part weight of 10 kg.

Your contact for mechanical engineering

Dr.-Ing. René Wilfried Scharn

Managing Director and Division Head for Special Machine Engineering

Tel: +49 3628 734-0

anfrage-smb@awm-tec.de