Initial situation / challenge

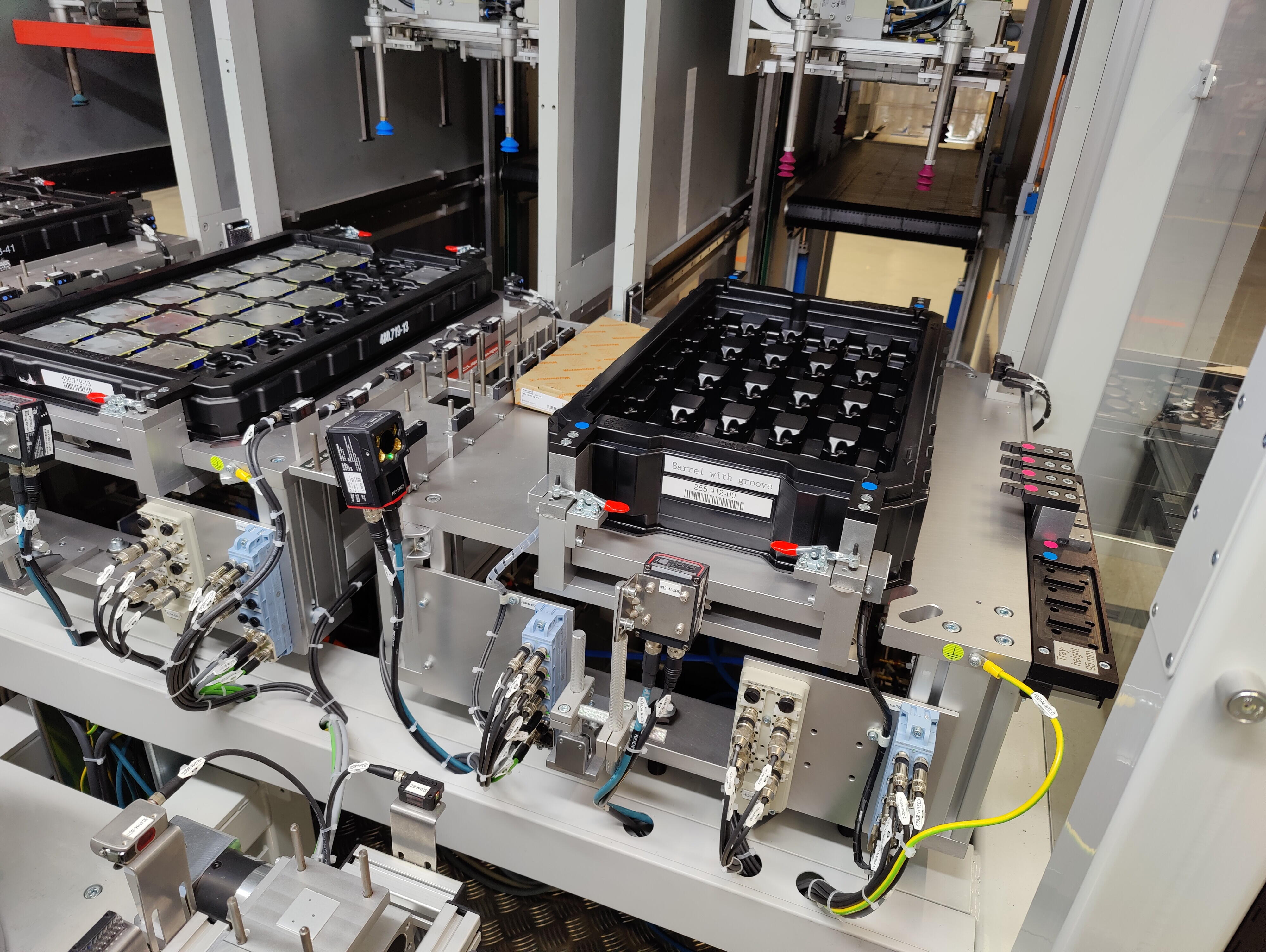

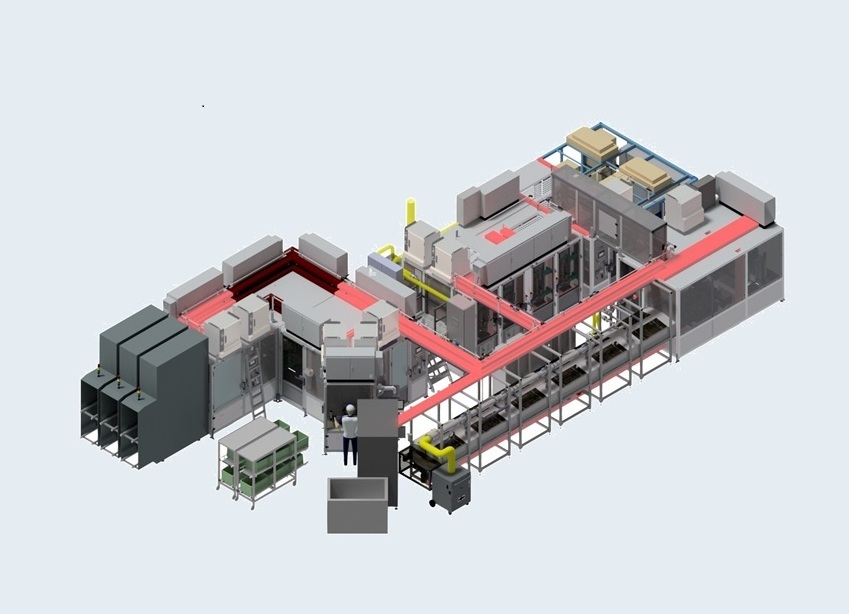

The customer needs a fully automated line for the production of LED lighting modules in 5 variants for car floodlights with manual testing and packaging space at the end. Material is fed in by 3 tray loaders on one side and manually on the other wide by insertion into workpiece carriers.

Industry: Automotive

Particular characteristics:

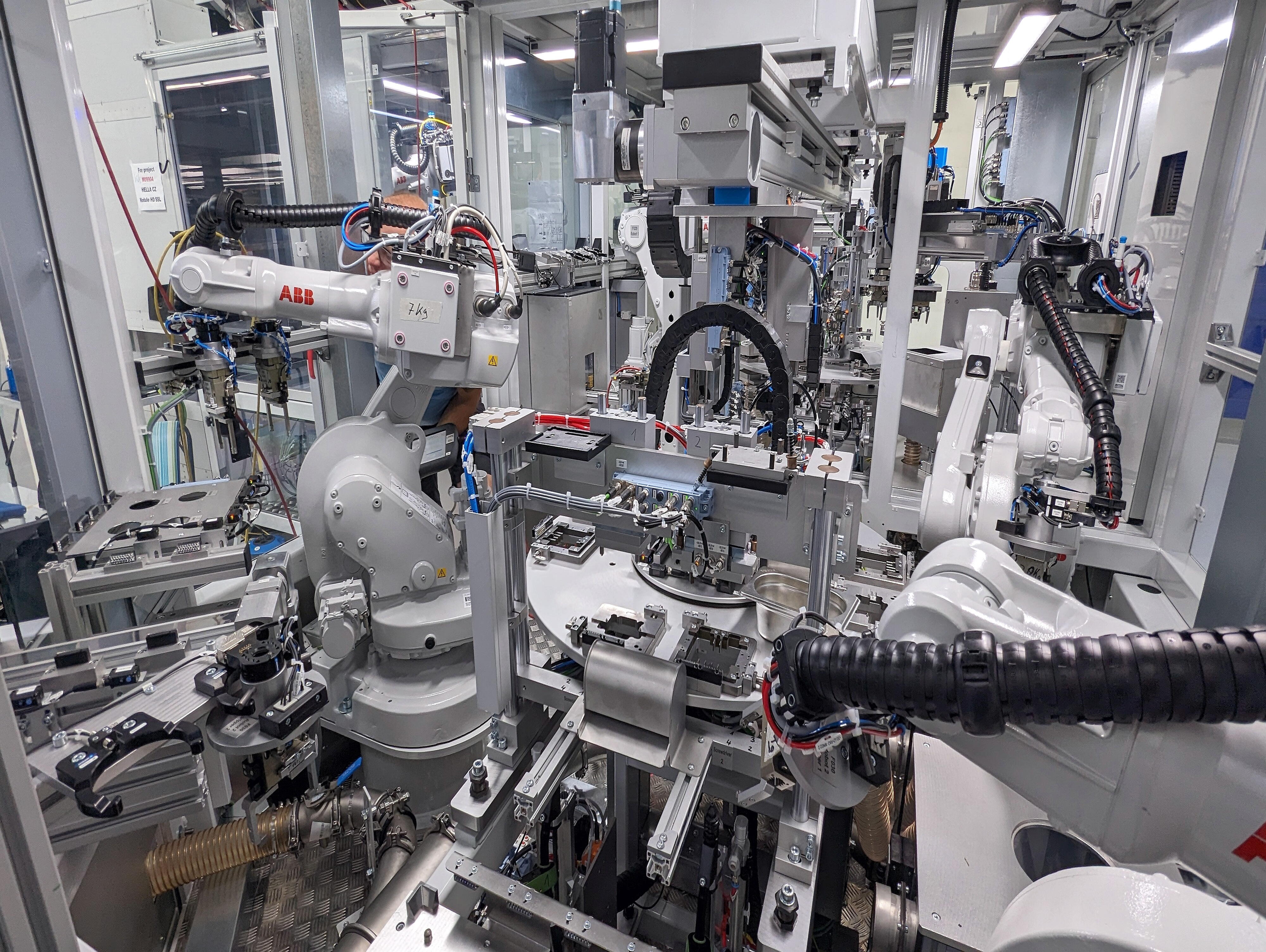

- Elaborate integration of 5 dosing processes and 10 technologies in one assembly line with collaboration between AWM and 3 technology partners [MRB, Proksys, Customer]

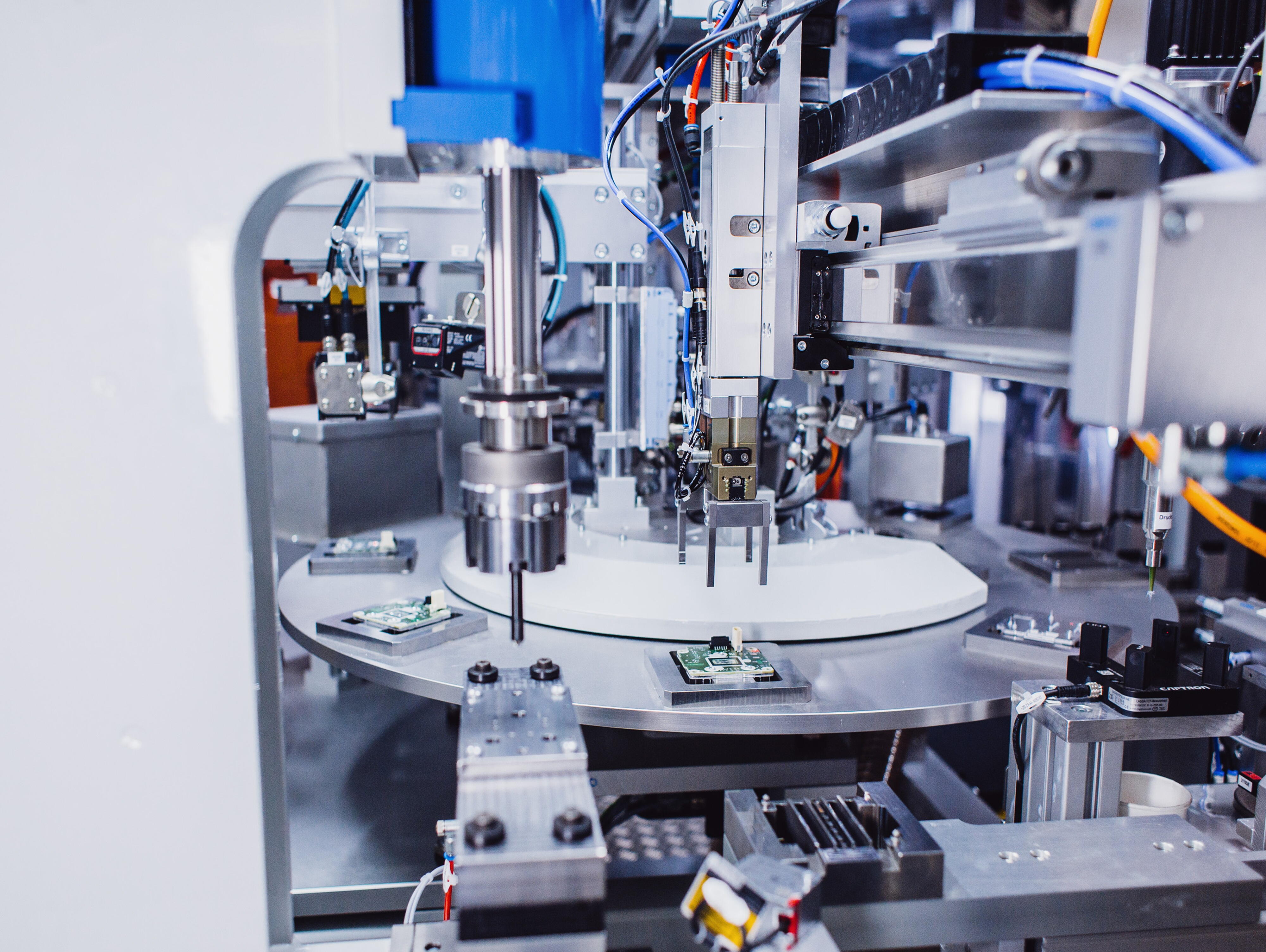

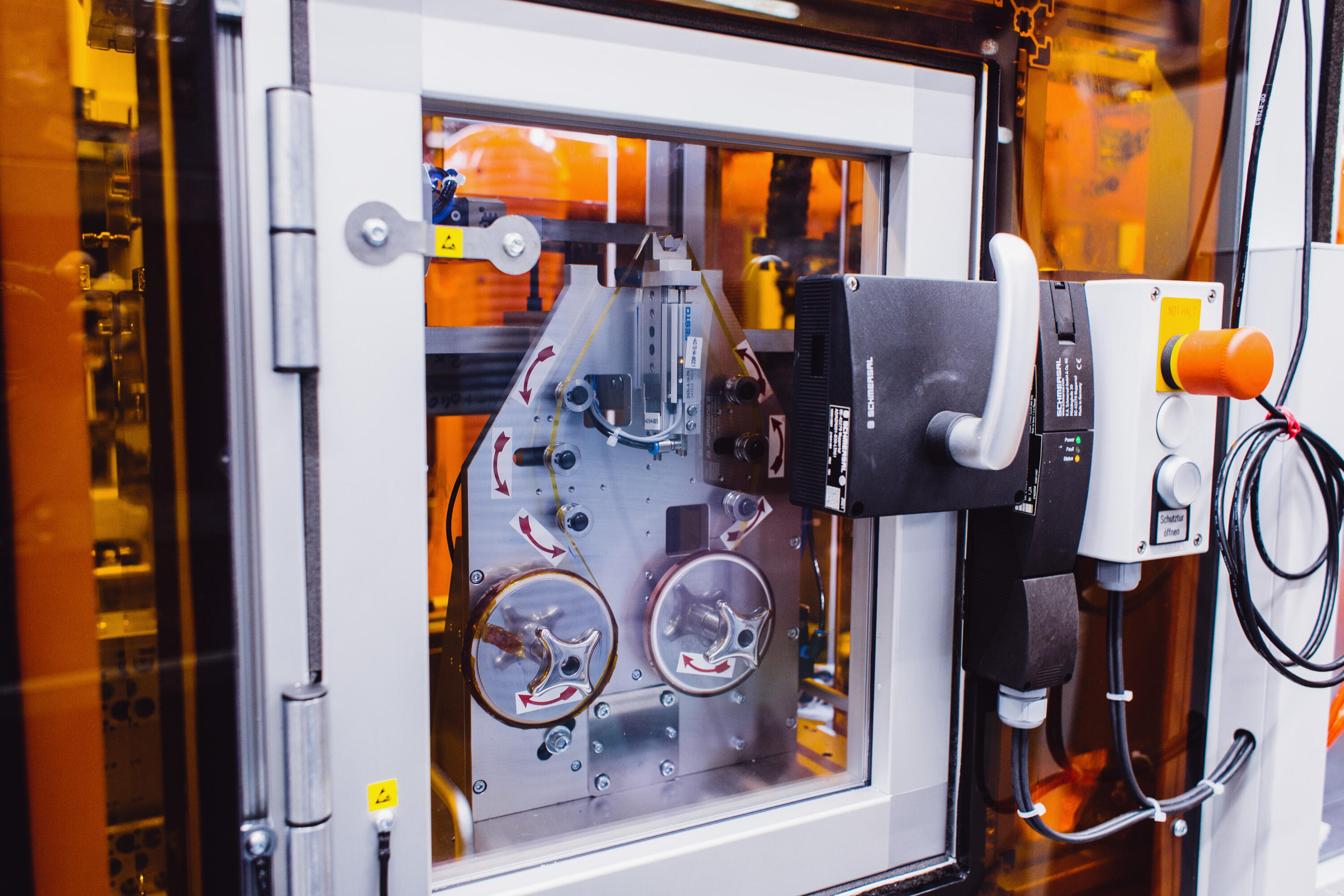

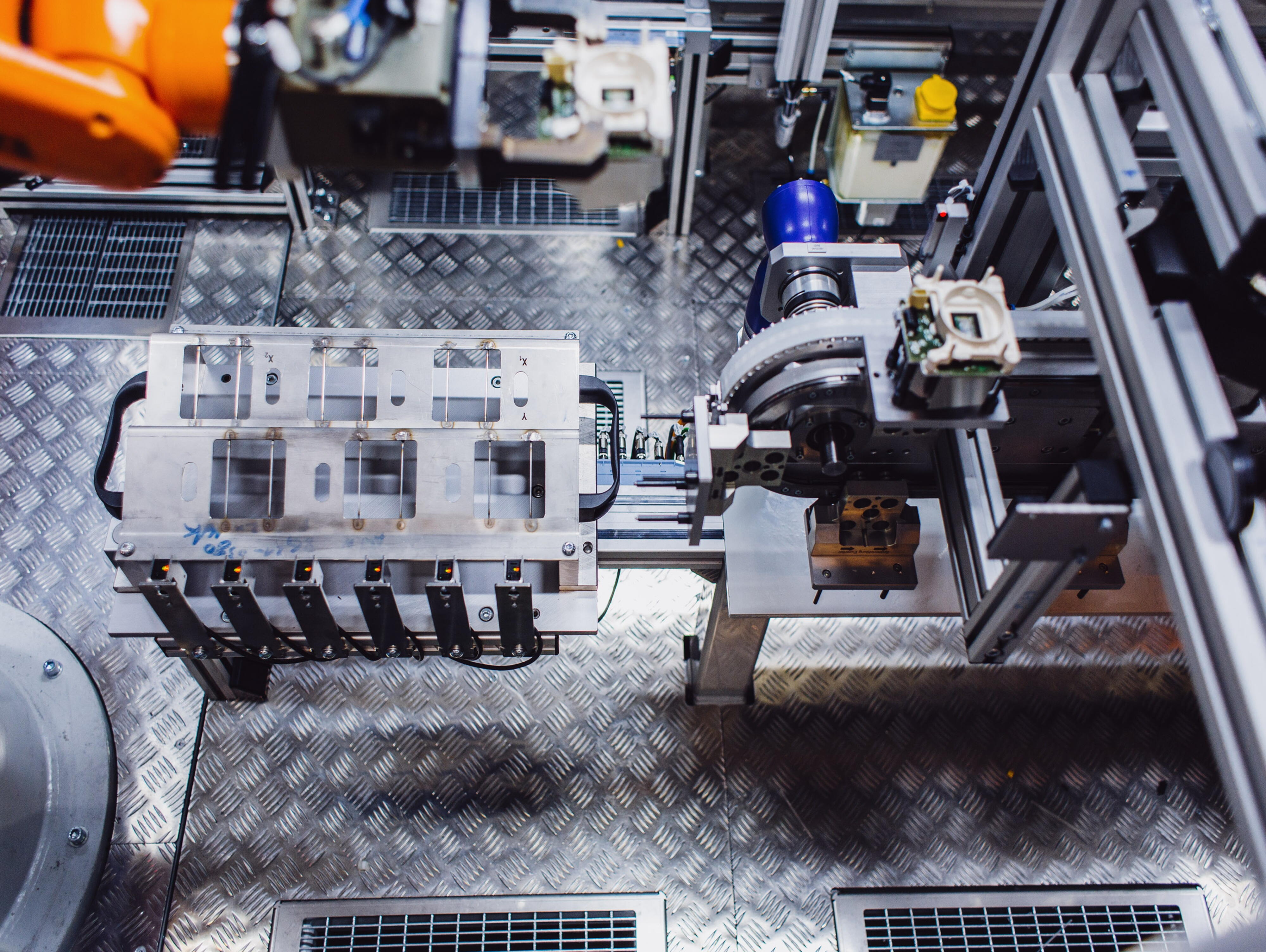

- High-precision alignment in lower µm range

Challenges:

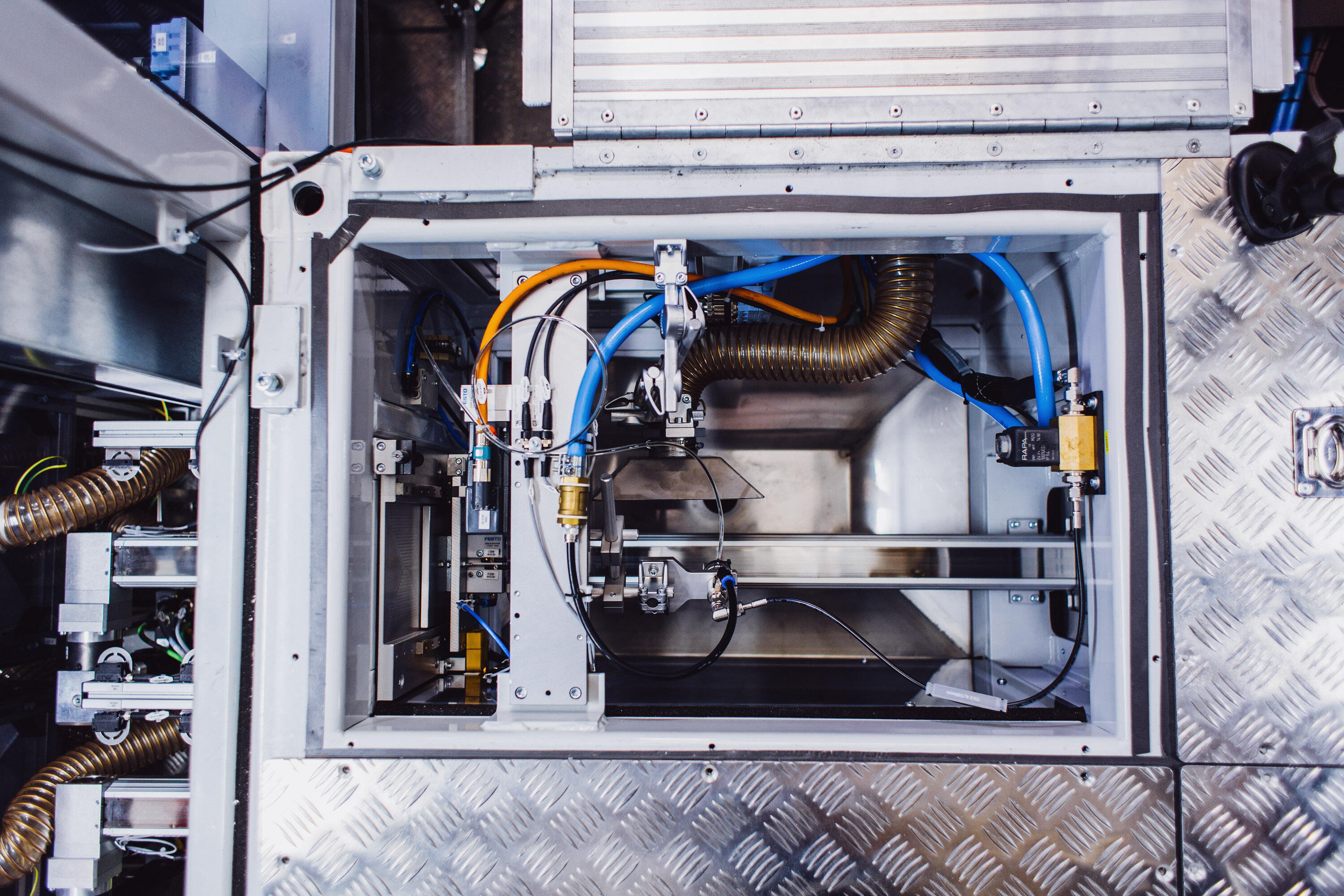

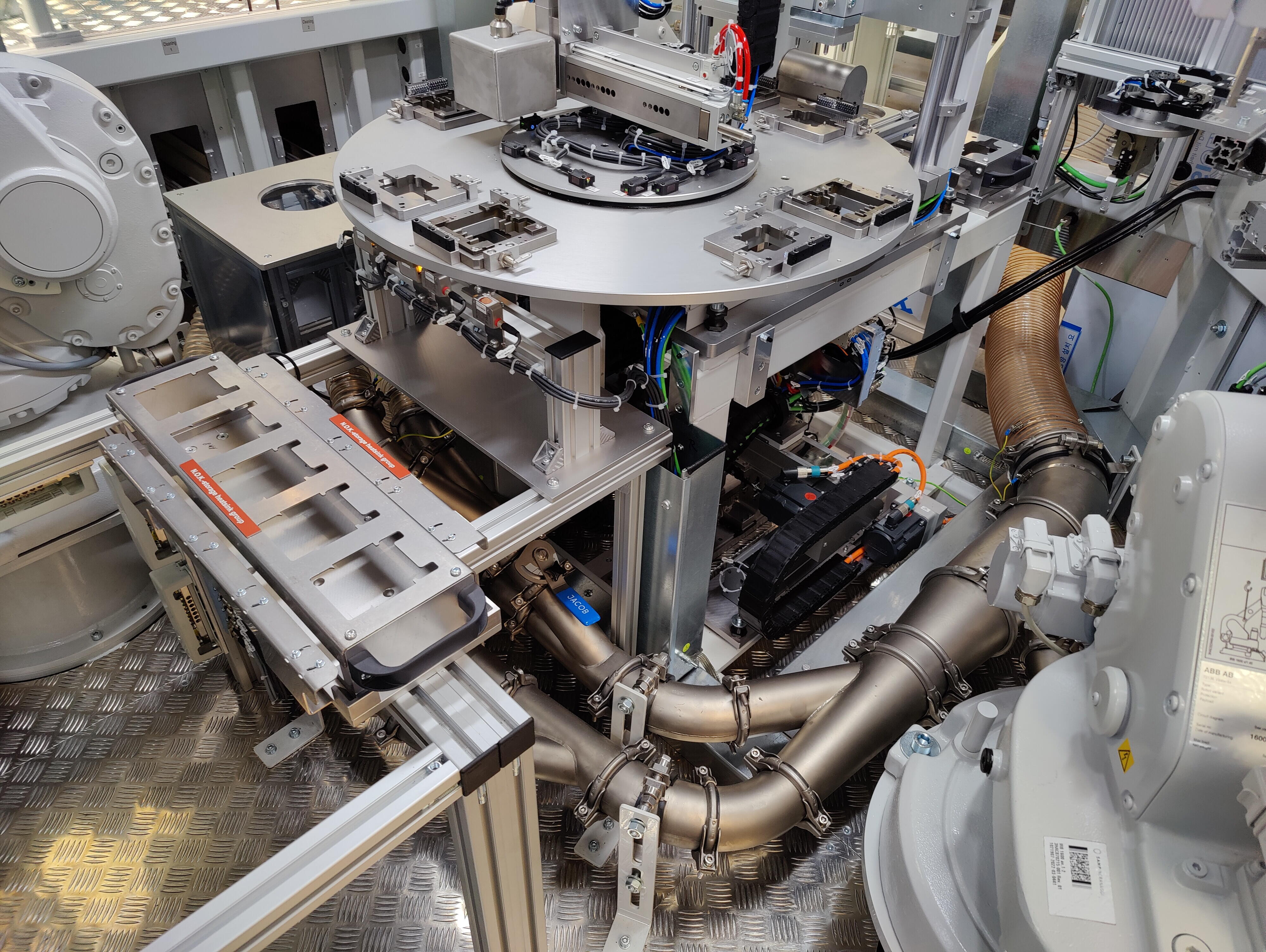

Various media need to be dosed (heat-conducting paste, spacer, silicone, UV adhesive) and the UV adhesive must be hardened and many technologies must be integrated (mounting, riveting, bolting, compressed air cleaning, CO2 cleaning, protective film removal, weighing).

Alignment of the lenses for the basic modules must be carried out in the lower µm range and therefore requires special axes with the highest precision. The alignment software is provided by the end customer and was integrated by our technology partner [MRB].

The modules need to be cleaned after every fundamental process step, 7x in total. At the critical point, after the removal of the protective film, successful cleaning must be reviewed using special image processing.

Solution / Implementation

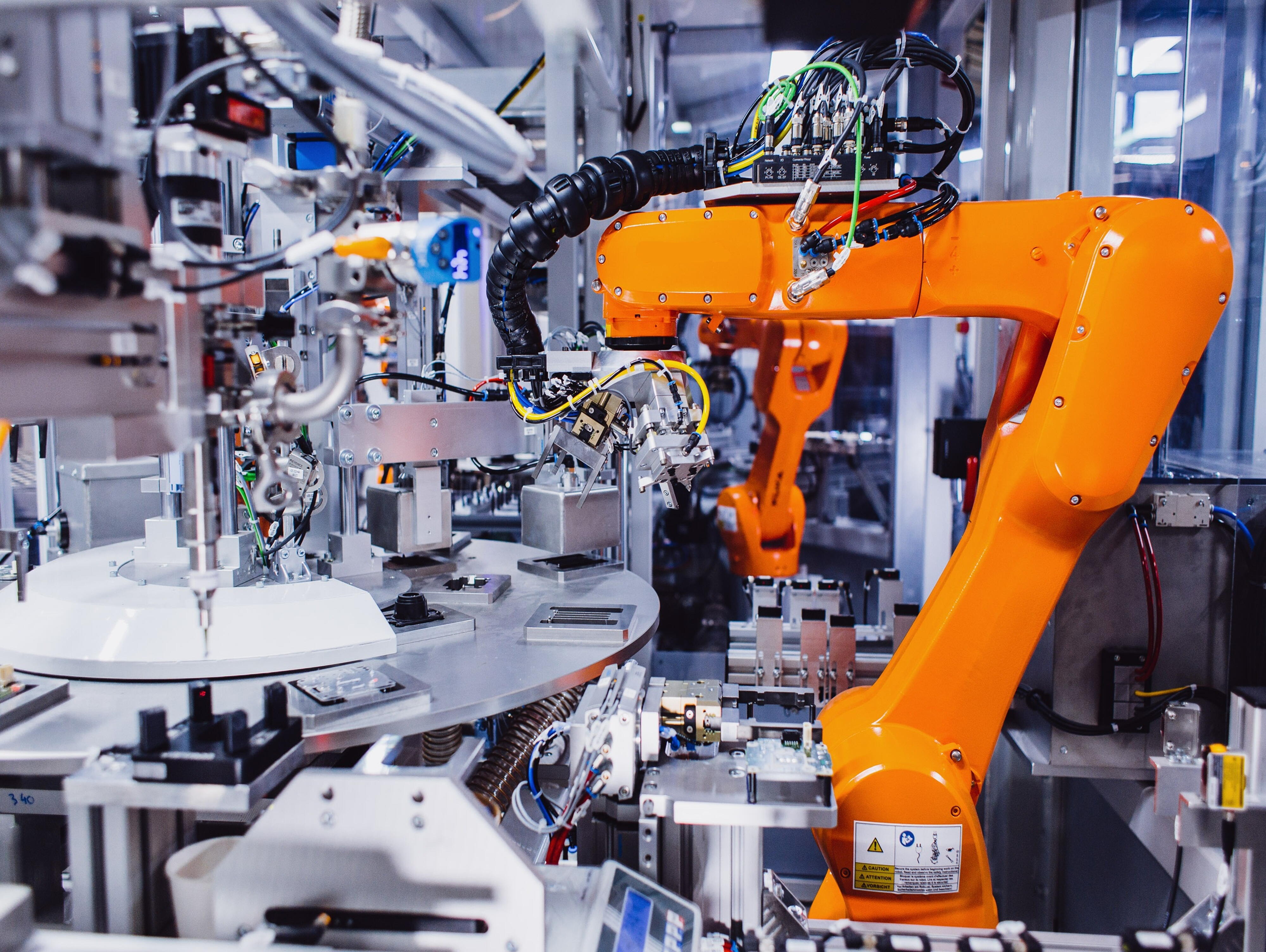

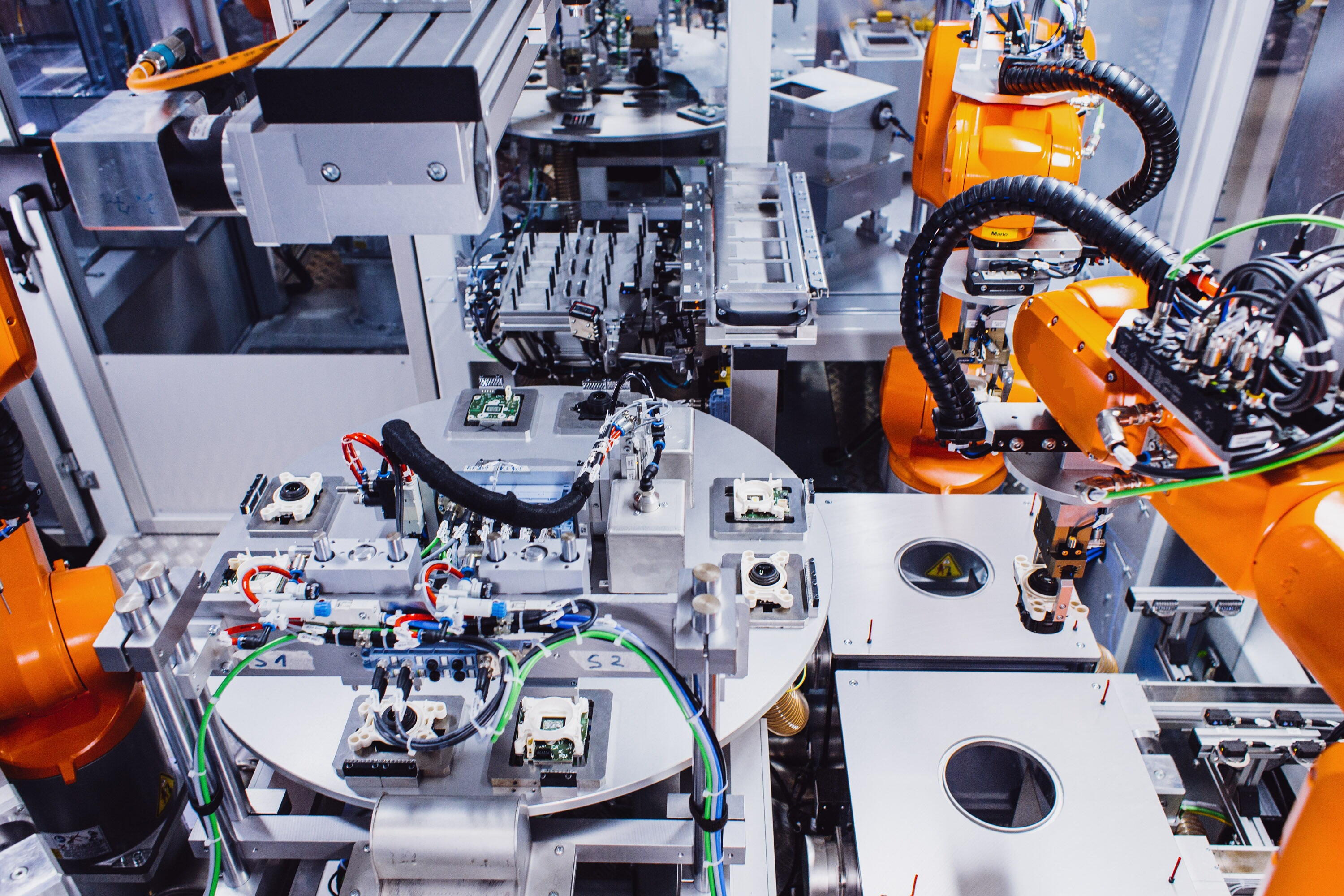

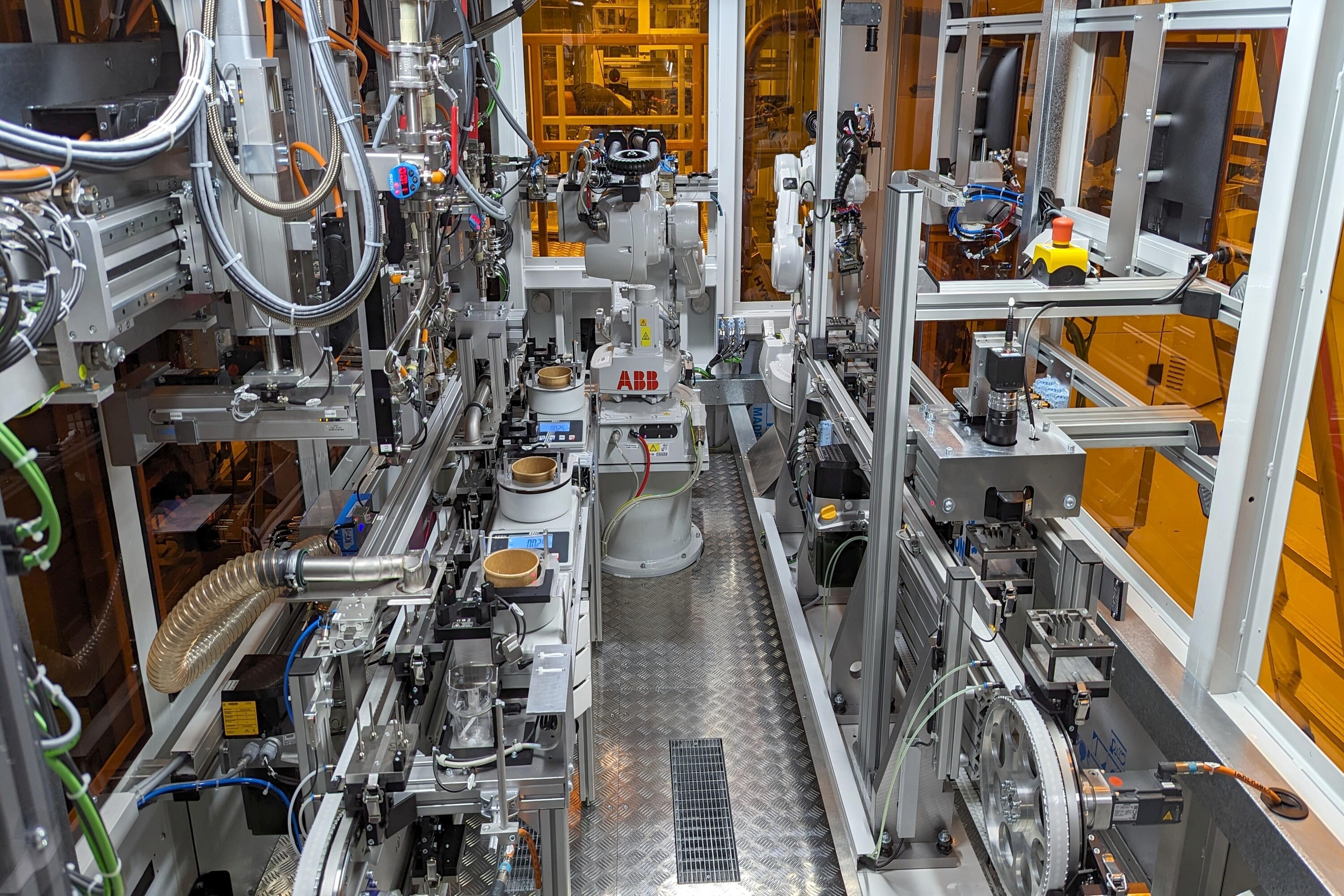

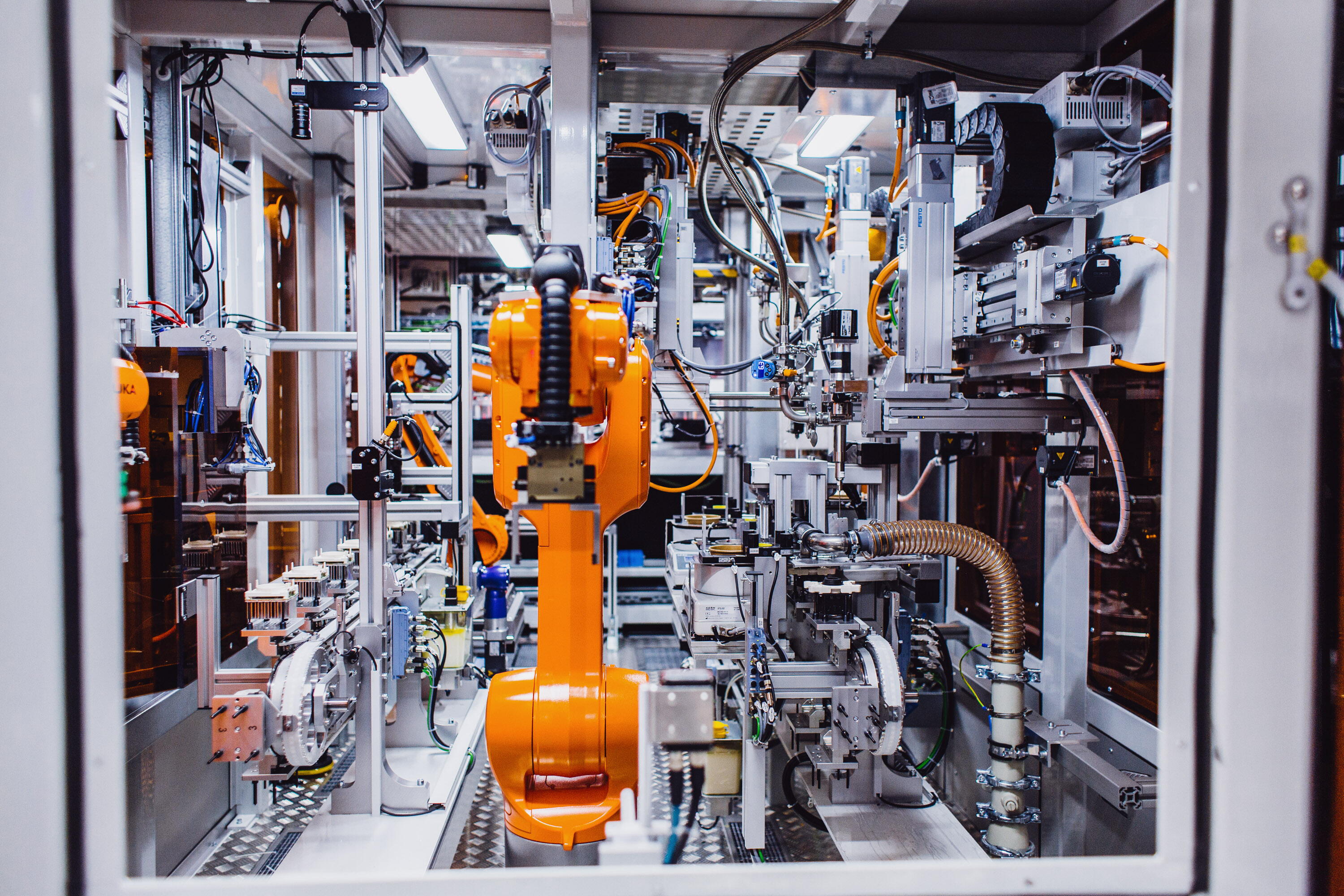

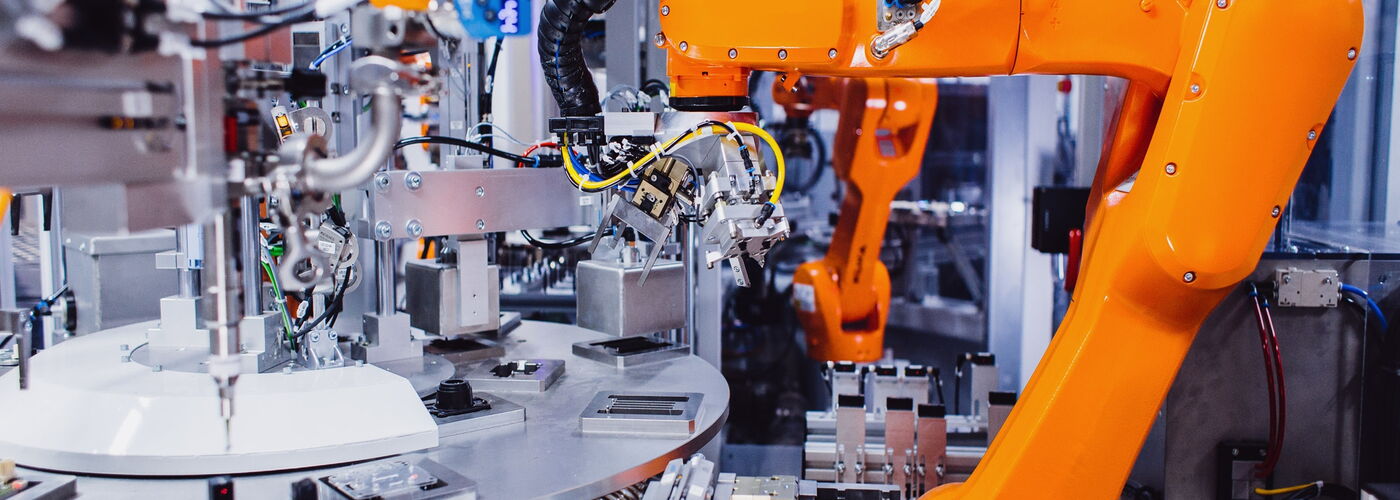

We developed and constructed a line with a total of 8 robots (some with triple grippers, some with automatic gripper change) and 6 handling systems that integrate all processes outlined above in a fully automated workflow.

A special image processing solution for detecting and counting particles in the range of 1/100 mm was developed and implemented.

The material flow is accomplished using robotic transfer, handling system transfer, on the rotary table and using takeover conveyors with workpiece carriers.

Despite its compact design, the line is readily accessible for maintenance and repairs. All media are supplied from the outside without process interruptions.

Result for the customer

Managing a highly complex assembly and alignment technology in 24/7 operation.

The available assembly space was observed, the challenging required cycle time was achieved and the required technical availability was exceeded.

Do you have any questions?

We will resolve your issue.

The quality and reliability of our special equipment is primarily determined by the quality of our mechanical components. We consider ourselves to be your solution provider for assembly and testing systems as well as sophisticated machines for plastic/metal-oriented parts and mechatronic systems up to a part weight of 10 kg.

Your contact for mechanical engineering

Dr.-Ing. René Wilfried Scharn

Managing Director and Division Head for Special Machine Engineering

Tel: +49 3628 734-0

anfrage-smb@awm-tec.de