Initial situation / challenge

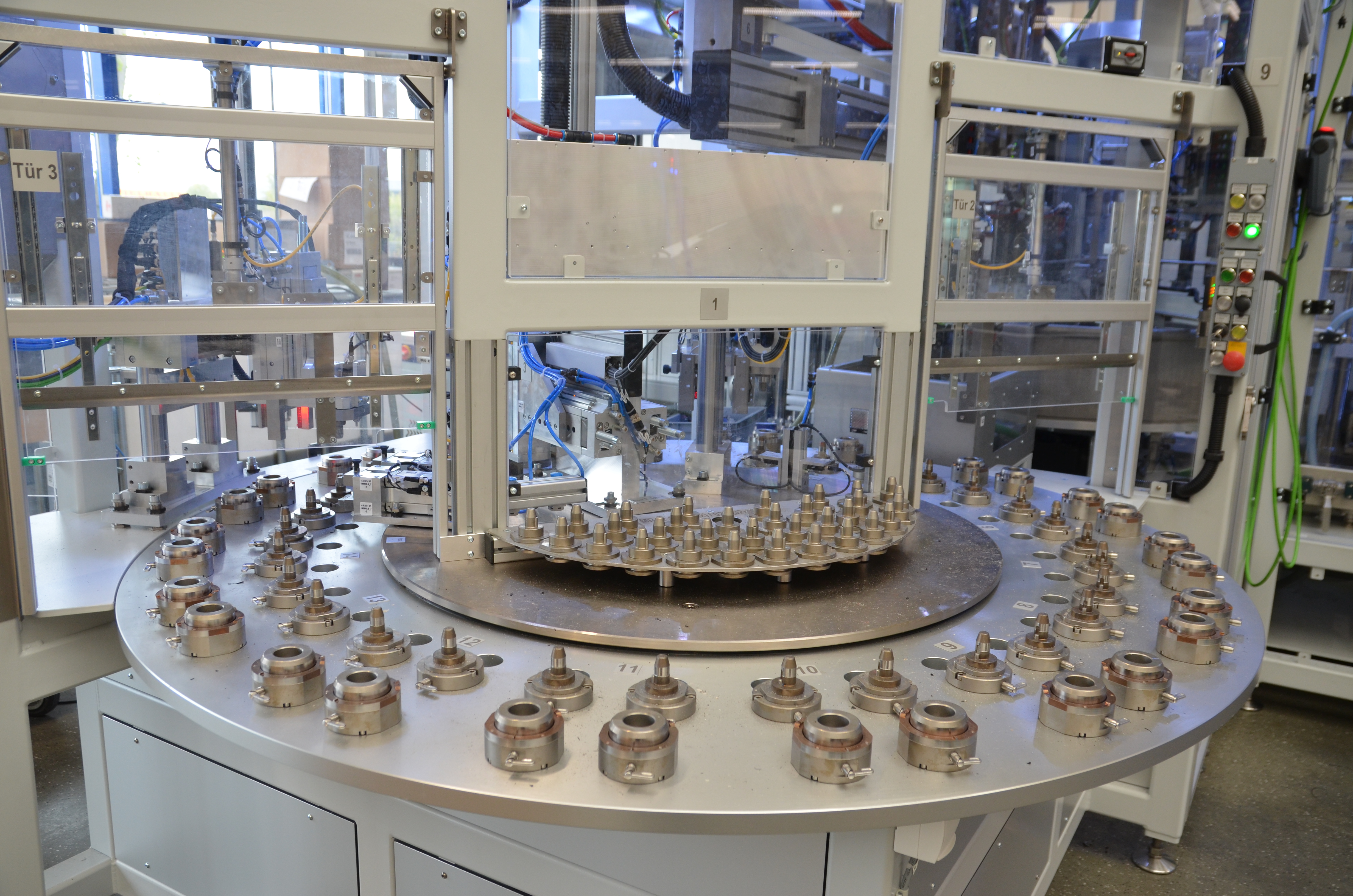

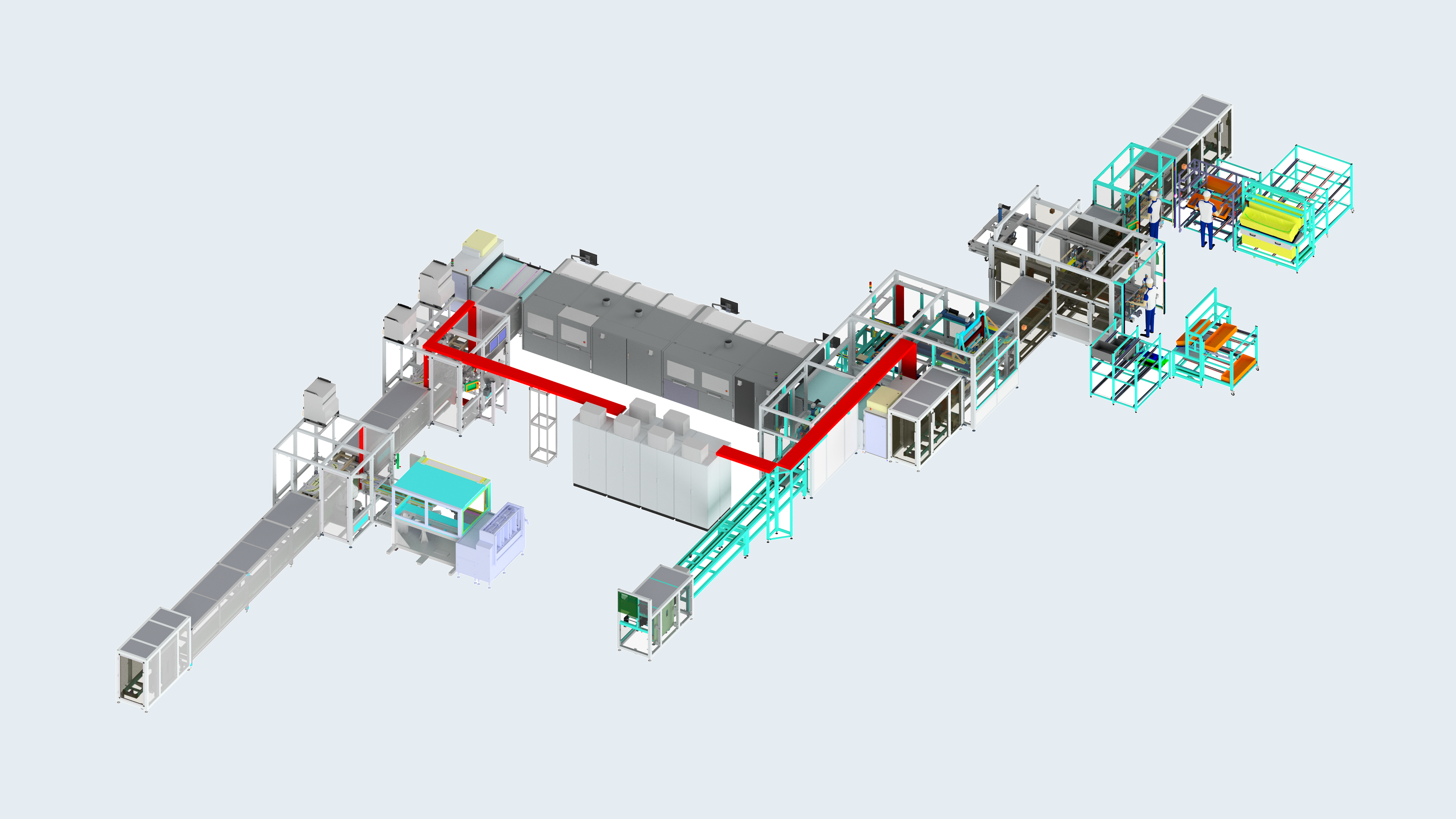

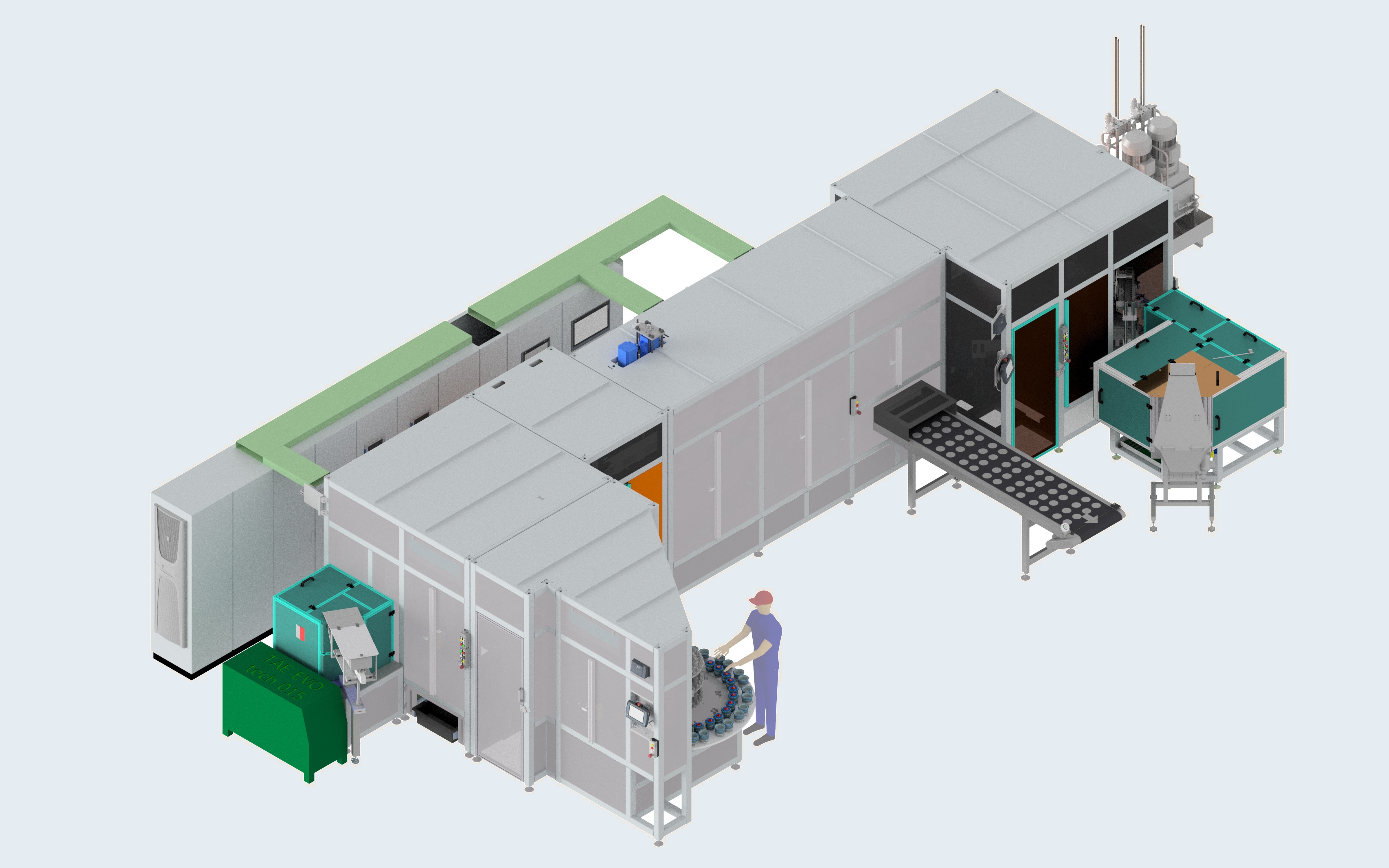

The customer required a fully automated system for the production of hydro assembly bearings in 3 variants for car chassis bearings with manual parts feed and pick-up conveyor. The system is to be designed for expansion to include further variants. The material is fed via a rotary table and various separating stations. The finished parts are removed from a cycle conveyor in a defined manner by the system operator.

Industry: Automotive

Special features:

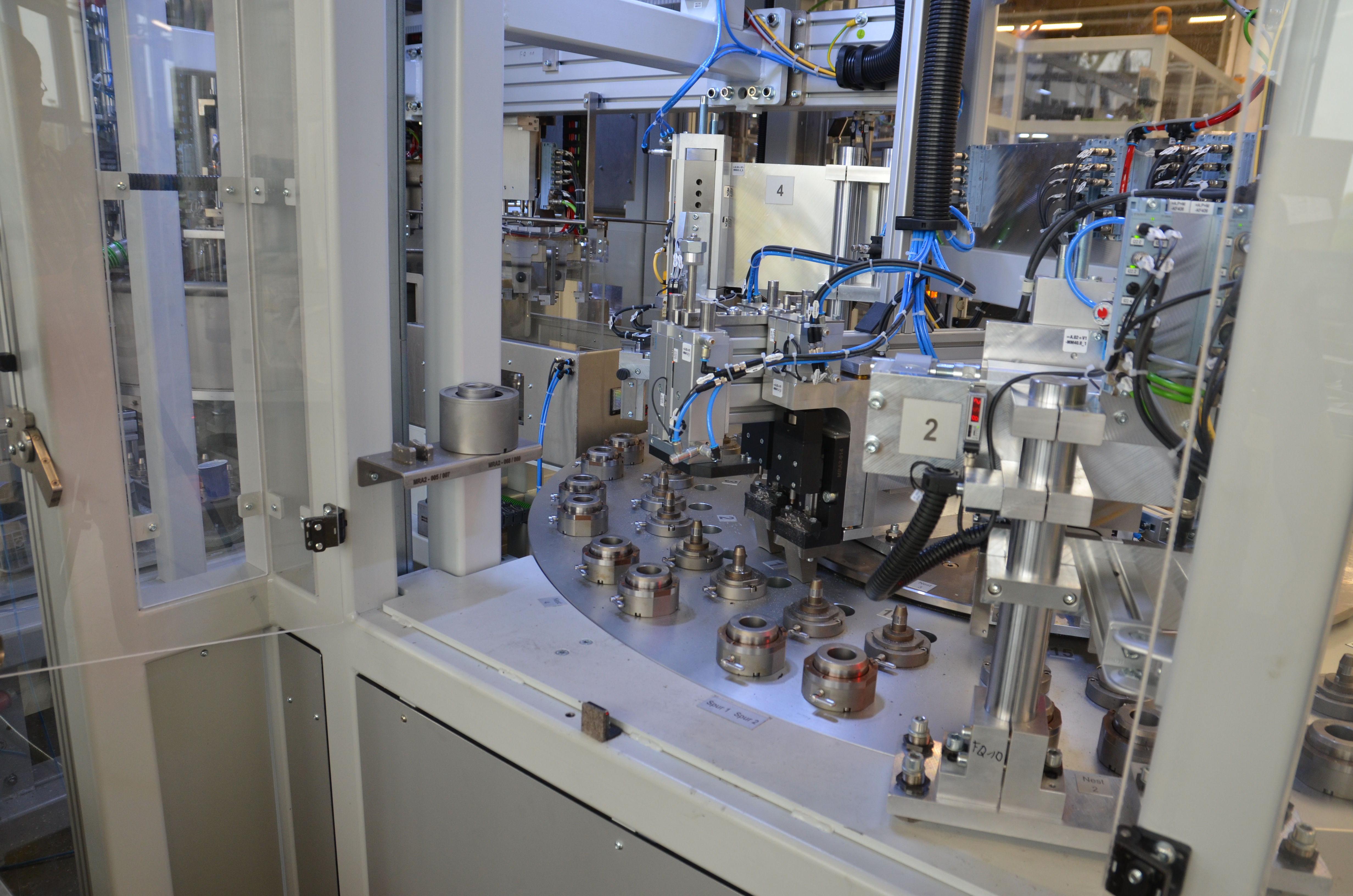

- Interlinking of several rotary tables and linear handling

- Assembly of components in glycol bath

- Mechanical processing of the finished part - roller burnishing and punching

- Hydraulic calibration of the finished part

- Process-safe intermediate and final inspections

- Extension of the system to other finished part variants

Challenges

- Ergonomic and reliable manual feeding of the components to be joined

- Automated bad part execution in bad part container according to error pattern

- End-of-line testing with external partner DYNA-MESS

Different components (steel-rubber) are added to a glycol bath and then mechanically formed (rolling and calibrating). The finished part is spun and tested in the system

Solution / Implementation

We developed and built a line with three rotary tables, two individual part feeders, 3 handling units and a finished part conveyor. The system is designed for a set-up time of XX minutes and allows the operator to carry out a vrain change in a short time.

Three welded steel structures form the basis of the system. These can be encapsulated for transportation and relocation.

Central stationary control cabinet to accommodate the power and control components. Two mobile panels for system operation and maintenance work.

The material flow is handled by handling systems, rotary tables in the wet and dry areas and indexing conveyors.

Despite its compact design, the line is easily accessible for maintenance and repair. All media are fed in from the outside without interrupting the process.

Result for the customer

We have successfully fulfilled our order and achieved the following:

1. undercutting the required cycle time by 5%

2. increase in technical availability to 97%

3. expansion of variants to seven

4. system expansion by four test stations and two processing stations

Do you have any questions?

We will resolve your issue.

The quality and reliability of our special equipment is primarily determined by the quality of our mechanical components. We consider ourselves to be your solution provider for assembly and testing systems as well as sophisticated machines for plastic/metal-oriented parts and mechatronic systems up to a part weight of 10 kg.

Your contact for mechanical engineering

Dr.-Ing. René Wilfried Scharn

Managing Director and Division Head for Special Machine Engineering

Tel: +49 3628 734-0

anfrage-smb@awm-tec.de