Initial situation / challenge

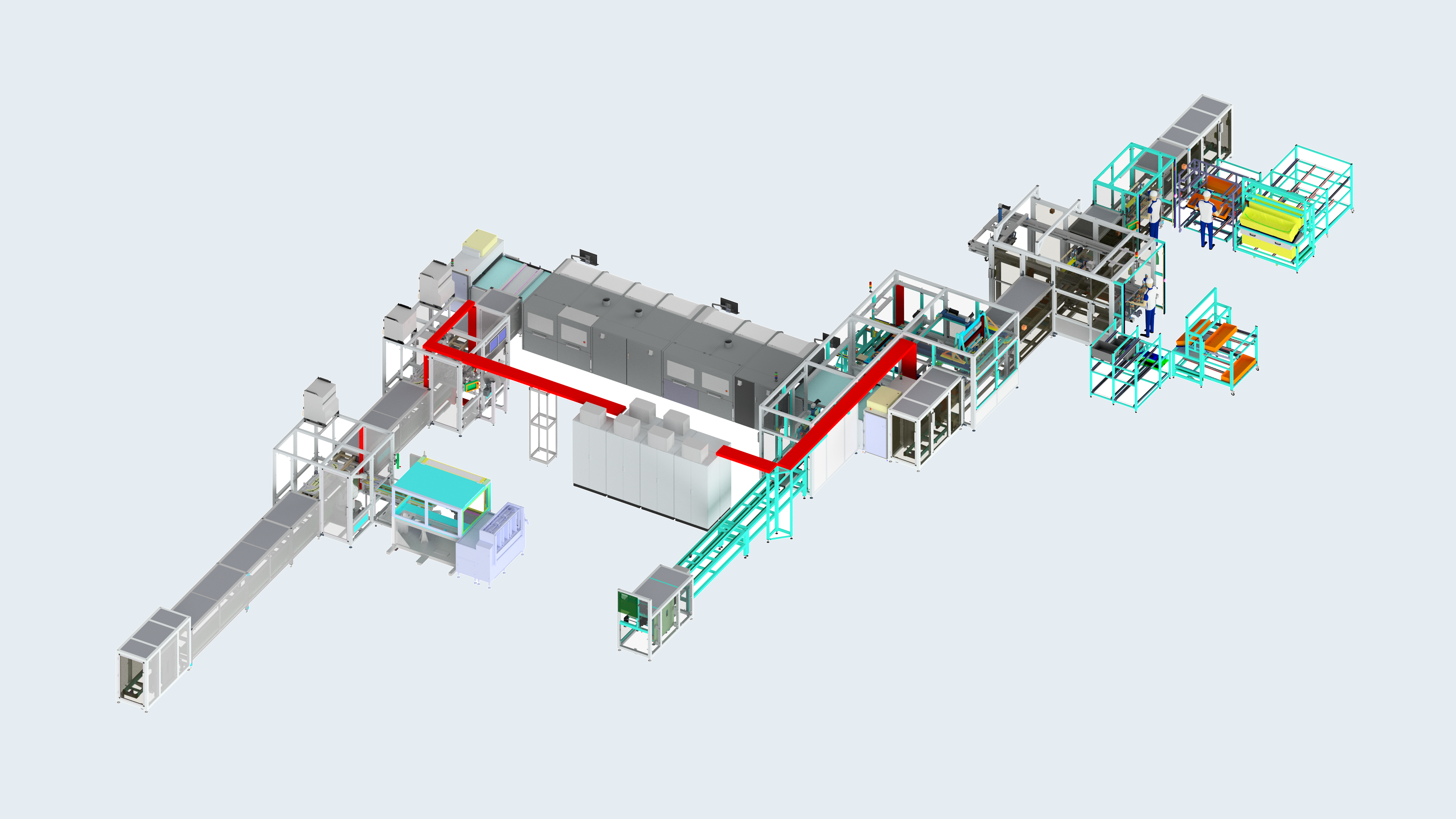

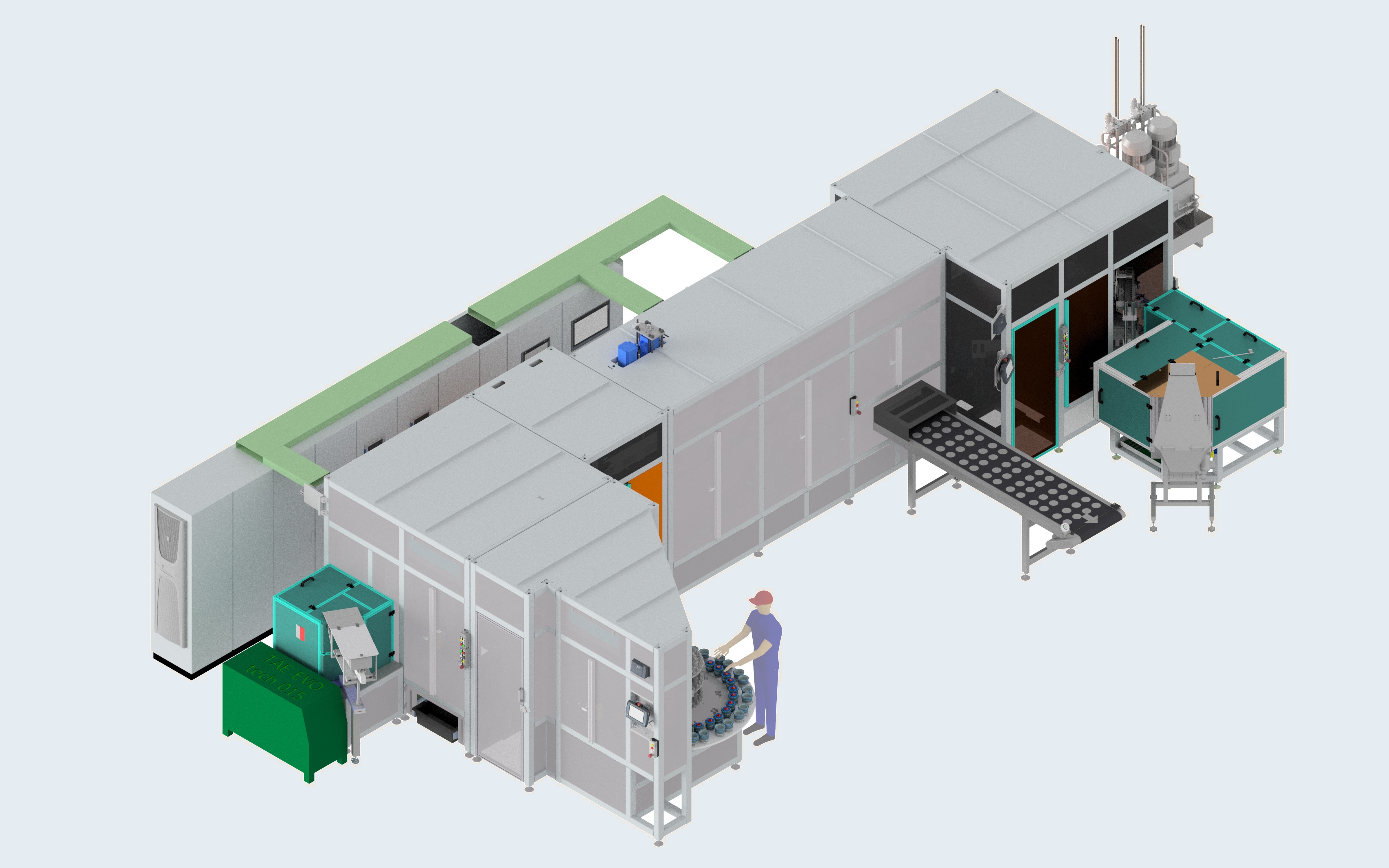

The customer needs a fully automated line for the production of LED interior lighting in 8 variants. This line must include all assembly steps between the depanelling system and the EOLT cell (end of line tester).

Industry: Automotive

Particular characteristics:

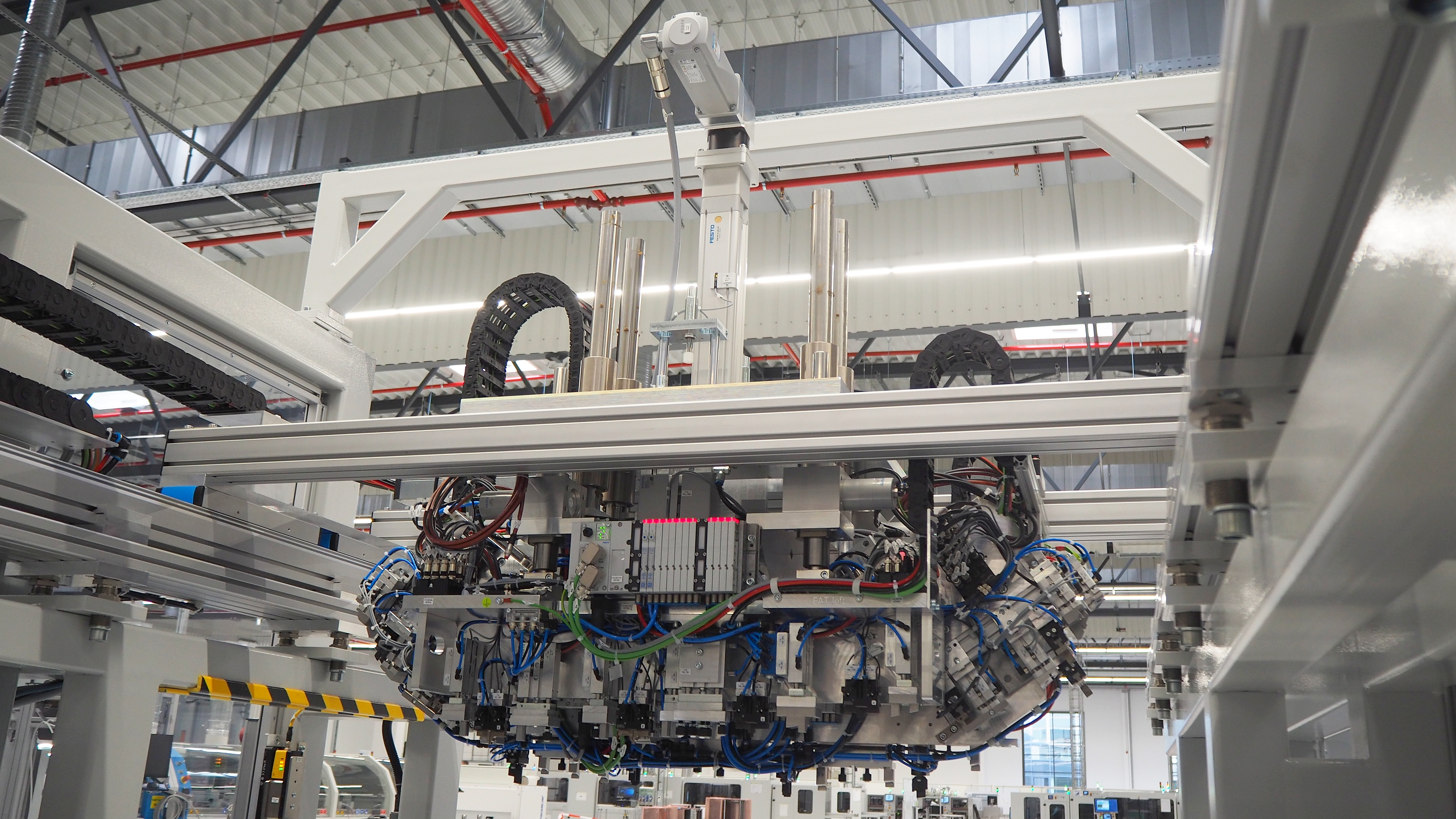

- Synchronised operation of 2 robots simultaneously for the same task;

- 4 mechanical engineers involved on the same line [Schunk depanelling system, AWM line, Seho soldering plant, EOLT UG Systems] and 1 technology partner [Proksys image processing]

Challenges

Jumpers made of bundle wire must be cut, bent and joined. The lighting modules comprise long slim plastic injection moulding parts. Neither of these are structurally stable, yet they must be securely joined during manufacture.

The success of critical assembly steps must be monitored via image processing.

Solution / Implementation

We developed and constructed an assembly line that met all the requirements outlined above.

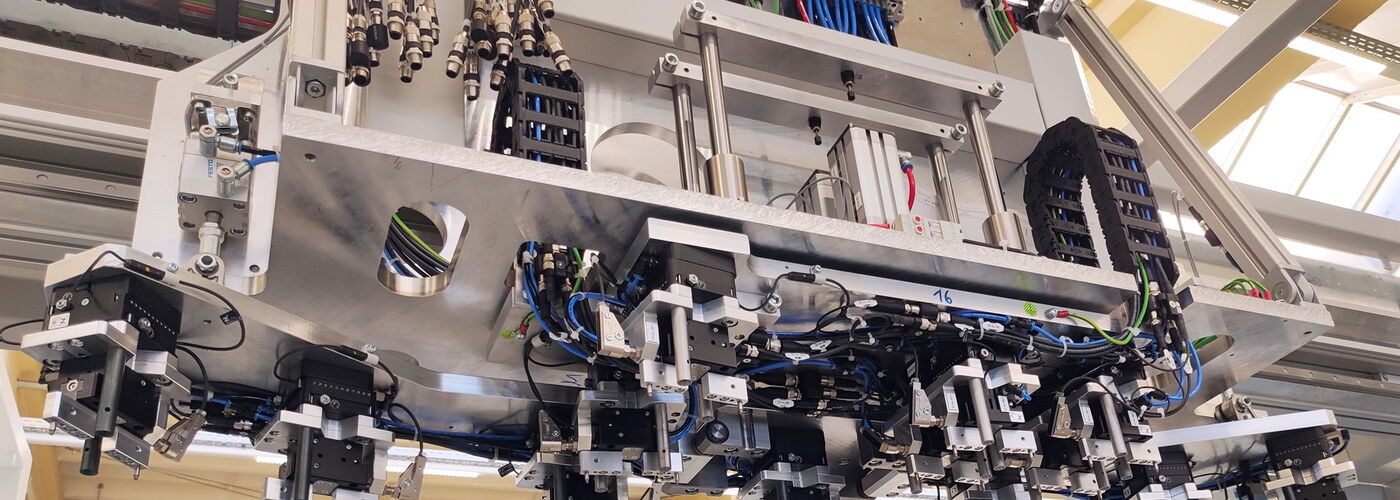

The punching and bending cell for jumpers includes 2 robots that grip the jumpers simultaneously on both sides and insert them into the PCB using synchronised movements, where they are then soldered.

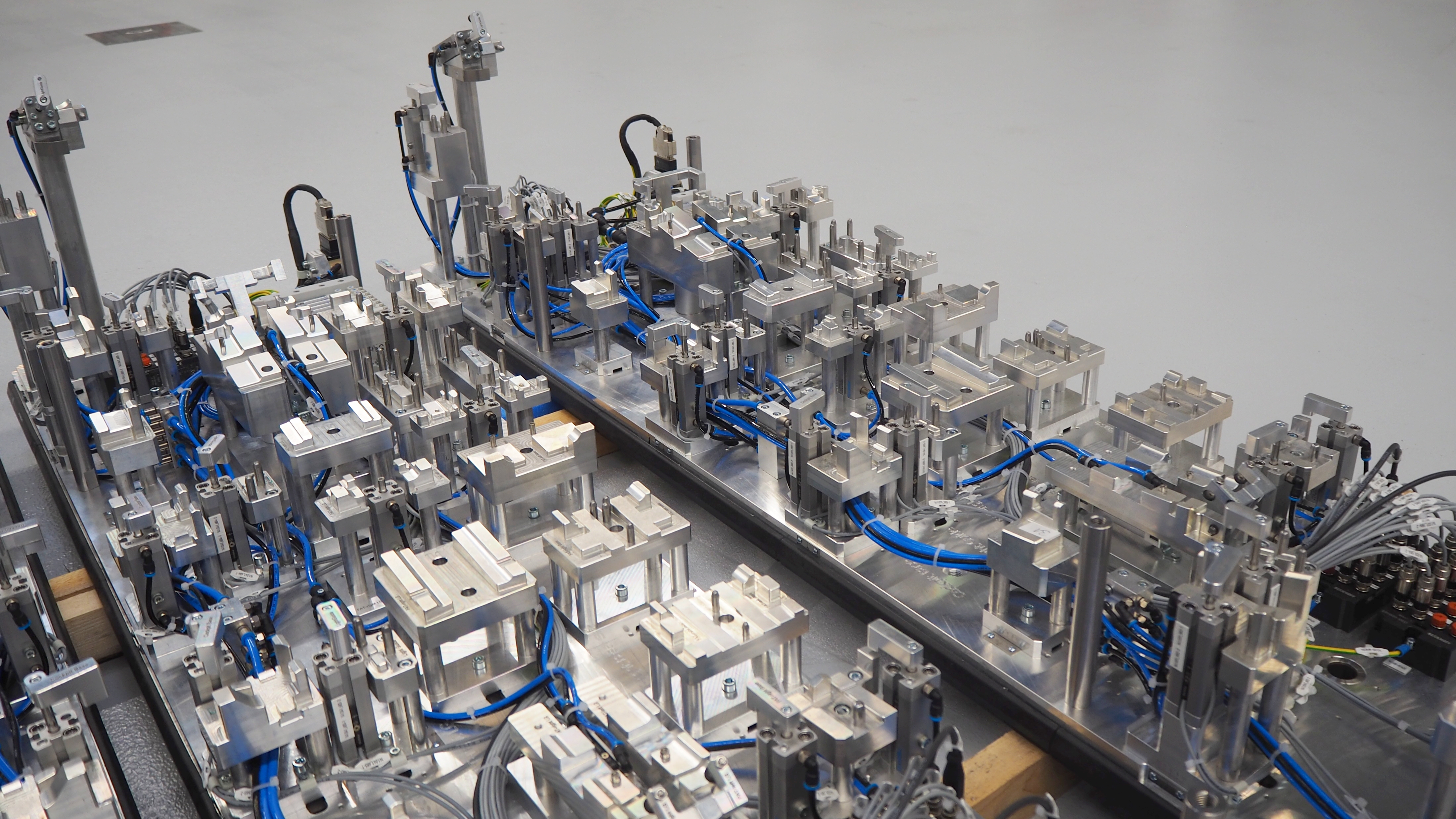

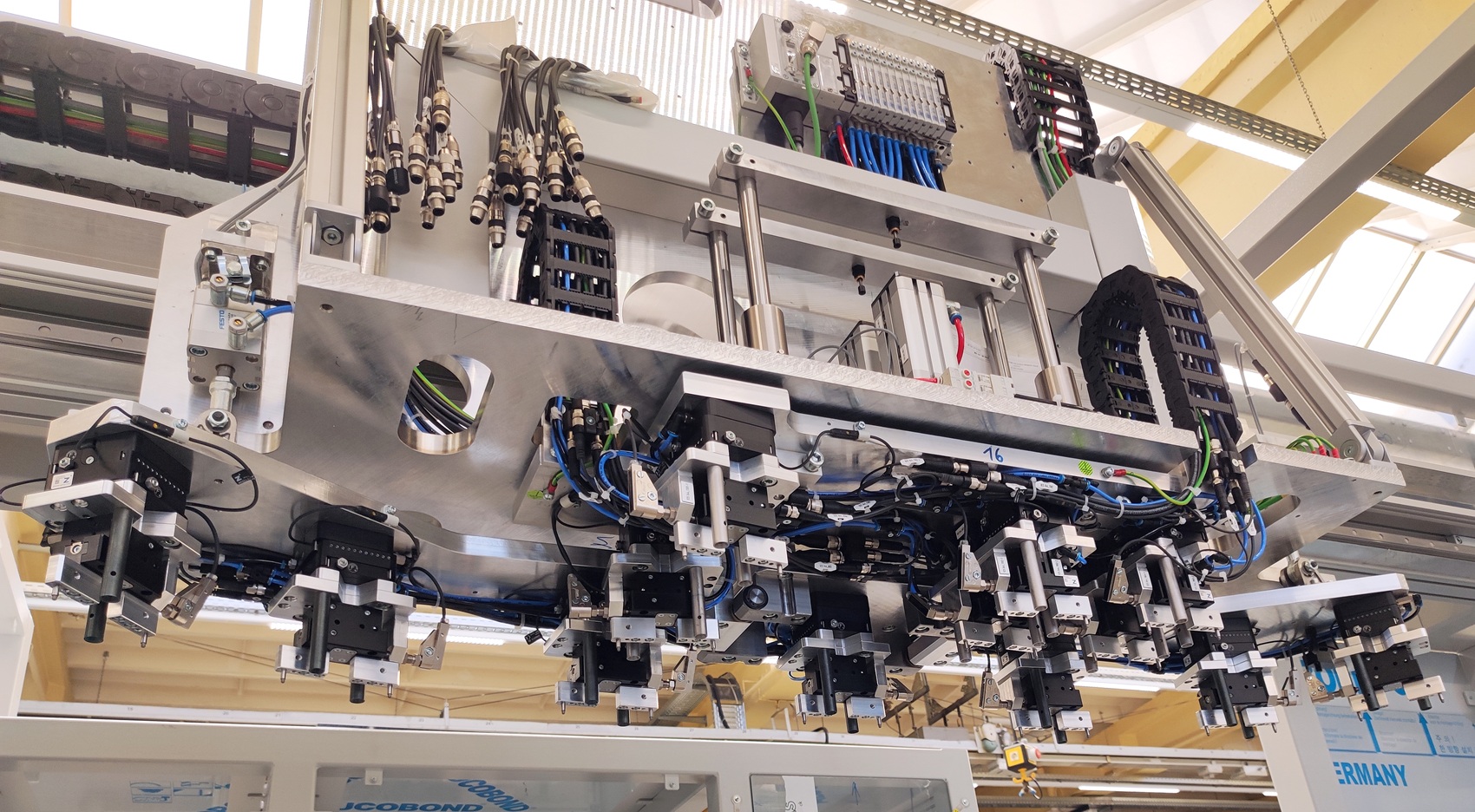

The final assembly cells include extremely large and complex grippers with up to 40 functional elements.

The material flow is accomplished using conveyor sections with workpiece carriers that are also large and complex in their design and functional elements.

Result for the customer

The challenging cycle time was achieved and the required technical availability was exceeded.

The line is technically sophisticated and operates profitably for the customer.

Do you have any questions?

We will resolve your issue.

The quality and reliability of our special equipment is primarily determined by the quality of our mechanical components. We consider ourselves to be your solution provider for assembly and testing systems as well as sophisticated machines for plastic/metal-oriented parts and mechatronic systems up to a part weight of 10 kg.

Your contact for mechanical engineering

Dr.-Ing. René Wilfried Scharn

Managing Director and Division Head for Special Machine Engineering

Tel: +49 3628 734-0

anfrage-smb@awm-tec.de